- What is Root Cause Analysis (RCA)?

- Key Principles of Root Cause Analysis

- How to Prepare for Root Cause Analysis?

- RCA Methodologies and Tools

- How to Conduct Root Cause Analysis?

- Root Cause Analysis Template

- Developing and Implementing Solutions

- Root Cause Analysis Examples

- Root Cause Analysis Best Practices

- Conclusion

Have you ever faced a recurring problem and wondered why it keeps happening despite your best efforts to fix it? Root Cause Analysis (RCA) is a powerful method designed to uncover the fundamental reasons behind such issues. Rather than just addressing surface-level symptoms, RCA dives deep into the underlying causes, helping you to identify and resolve the core issues that lead to recurring problems.

This guide will walk you through the essential principles, methodologies, and best practices of RCA. By understanding and applying these techniques, you’ll be better equipped to tackle problems effectively, enhance your processes, and achieve lasting improvements in your organization or system. Whether you’re dealing with operational inefficiencies, quality concerns, or any other persistent issue, RCA provides the tools and insights needed to address problems at their root and prevent them from happening again.

What is Root Cause Analysis (RCA)?

Root Cause Analysis (RCA) is a systematic approach used to identify the underlying causes of problems or issues within a process, system, or organization. The goal of RCA is to uncover the fundamental reasons why a problem occurred, rather than just addressing its symptoms. By understanding and resolving the root causes, you can implement solutions that prevent the issue from recurring and improve overall performance.

RCA involves several key steps:

- Problem Identification: Clearly define the problem you are facing. This includes understanding what the problem is, where it occurs, and how it impacts the system or process.

- Data Collection: Gather relevant data and evidence related to the problem. This might include performance metrics, incident reports, and observations.

- Cause Analysis: Use various techniques and tools to analyze the data and identify potential causes. Common methods include the Five Whys technique, Fishbone Diagrams, and Fault Tree Analysis.

- Root Cause Identification: Determine the underlying cause(s) of the problem by tracing back from symptoms to the root cause.

- Solution Development: Develop and implement solutions that address the identified root causes to prevent the problem from recurring.

- Verification: Monitor and verify that the implemented solutions effectively resolve the issue and that no new problems have emerged.

By focusing on the root causes, RCA helps you achieve more effective and lasting solutions compared to simply fixing symptoms.

Importance and Benefits of RCA

Root Cause Analysis is crucial for organizations and systems because it offers numerous benefits that enhance operational efficiency, improve quality, and reduce costs. Here’s why RCA is important and the advantages it provides:

- Prevents Recurrence: By addressing the root causes of problems, RCA helps prevent the same issues from recurring. This leads to more sustainable solutions and reduces the likelihood of future disruptions.

- Improves Problem-Solving: RCA provides a structured approach to problem-solving. It helps you identify not just what went wrong but why it went wrong, allowing for more targeted and effective solutions.

- Enhances Process Efficiency: Identifying and eliminating root causes can streamline processes and eliminate inefficiencies. This leads to improved productivity and performance.

- Reduces Costs: Addressing root causes often reduces the need for repeated fixes and minimizes the impact of issues on operations. This can result in significant cost savings over time.

- Boosts Quality: By solving underlying issues, RCA helps improve the quality of products and services. This can enhance customer satisfaction and reduce defects or failures.

- Fosters a Culture of Continuous Improvement: RCA encourages a proactive approach to problem-solving and continuous improvement. It helps build a culture where issues are addressed systematically and learnings are integrated into practices.

- Facilitates Better Decision-Making: RCA provides insights into the factors affecting performance and helps in making informed decisions based on a deeper understanding of underlying issues.

- Enhances Accountability: By clearly identifying the root causes of problems, RCA helps establish accountability and ensures that appropriate measures are taken to address and prevent issues.

Root Cause Analysis is a valuable tool for any organization or system. It not only helps resolve existing problems but also fosters a proactive approach to preventing future issues, ultimately leading to improved efficiency, quality, and overall performance.

Key Principles of Root Cause Analysis

Root Cause Analysis (RCA) is built on several fundamental principles that guide you in uncovering and addressing the core issues behind problems. These principles ensure that the analysis is thorough and effective, leading to sustainable solutions.

Understanding Cause and Effect

The principle of cause and effect is central to RCA. It’s based on the idea that every problem is a result of a sequence of events or factors. By understanding these relationships, you can trace the problem back to its origin.

When applying this principle, consider:

- Direct Causes: Immediate factors that lead to the problem. For instance, if a machine stops working, a direct cause might be a mechanical failure.

- Indirect Causes: Underlying factors that contribute to direct causes. In the machine example, indirect causes could include poor maintenance practices or lack of training.

To effectively use cause and effect analysis:

- Map Out the Process: Create a detailed flowchart of the process where the problem occurred. This helps in visualizing how different factors interact.

- Identify Relationships: Look for patterns and connections between different causes. For example, a delay in the supply chain could be linked to multiple factors, such as vendor reliability and internal logistics.

The Five Whys Technique

The Five Whys technique is a simple yet powerful method for identifying the root cause of a problem. It involves asking “why” repeatedly until you reach the fundamental cause.

Here’s how to use the Five Whys technique:

- State the Problem Clearly: Begin with a clear, concise statement of the problem. For example, “The delivery trucks are consistently late.”

- Ask “Why?”: Ask why the problem occurs. For example, “Why are the trucks late?” The answer might be, “Because the loading process is slow.”

- Repeat the Process: Continue asking why for each answer. For example, “Why is the loading process slow?” The answer might be, “Because the equipment is outdated.” Keep asking until you reach the root cause.

Example:

- Problem: The software application crashes frequently.

- Why? The application has a memory leak.

- Why? The code is not releasing memory properly.

- Why? There is a bug in the memory management module.

- Why? The bug was introduced in the last update.

- Why? The update was not thoroughly tested.

This technique helps to drill down past superficial issues to discover the underlying problem that needs addressing.

Fishbone Diagram (Ishikawa)

The Fishbone Diagram, also known as the Ishikawa Diagram or Cause-and-Effect Diagram, provides a visual representation of potential causes of a problem. It helps in categorizing and organizing these causes systematically.

To create a Fishbone Diagram:

- Draw the Diagram: Start with a central “spine” that represents the main problem. Branches off the spine represent major categories of causes.

- Identify Categories: Common categories include People, Processes, Equipment, Materials, Environment, and Management. Each category is a “bone” of the fish.

- List Causes: For each category, list potential causes related to that area. For example, under “Equipment,” you might list “Outdated technology” or “Frequent breakdowns.”

- Analyze and Prioritize: Review the diagram to identify the most likely causes. This visual tool helps you see where the problem may stem from and prioritize which areas to address first.

Example: If a manufacturing line is experiencing frequent delays, the Fishbone Diagram might show categories like Machinery (e.g., breakdowns), People (e.g., insufficient training), Processes (e.g., inefficient workflows), and Materials (e.g., supply issues).

Failure Mode and Effects Analysis (FMEA)

Failure Mode and Effects Analysis (FMEA) is a systematic method used to evaluate potential failure modes within a system and their impacts. It helps prioritize issues based on their severity, occurrence, and detectability.

To conduct an FMEA:

- Identify Failure Modes: List all potential ways in which a process or product could fail. For example, in a car engine, failure modes could include overheating or oil leaks.

- Assess Effects: Determine the effects of each failure mode. For example, overheating could lead to engine damage.

- Evaluate Severity: Rate the severity of each effect on a scale, such as 1 to 10, where 10 represents the most severe impact.

- Determine Occurrence: Assess how likely each failure mode is to occur, using a similar scale.

- Evaluate Detectability: Determine how easily the failure can be detected before it causes a problem.

- Calculate Risk Priority Number (RPN): Multiply the severity, occurrence, and detectability ratings to get the RPN. Higher RPNs indicate higher risk and should be prioritized for corrective action.

Example: If a new medical device has a potential failure mode of “battery depletion,” FMEA would assess the impact (e.g., device failure), the likelihood of battery depletion (e.g., often or rarely), and how easily it can be detected (e.g., with or without warning indicators).

By applying these principles—understanding cause and effect, using the Five Whys technique, creating Fishbone Diagrams, and conducting FMEA—you can effectively uncover the root causes of problems and develop targeted solutions.

How to Prepare for Root Cause Analysis?

Successful Root Cause Analysis (RCA) begins with thorough preparation. This involves clearly defining the problem, assembling the right team, and gathering relevant data. Each of these steps is crucial to ensure that your analysis is effective and leads to meaningful solutions.

1. Identify the Problem

Accurate problem identification is the first step in RCA. It’s essential to define the issue clearly and precisely to ensure that the analysis focuses on the right area.

Start by articulating the problem statement. This should be specific and descriptive, outlining what the problem is, where it occurs, and how it impacts the system or process. For instance, instead of stating a vague problem like “decreased productivity,” specify “production line output has decreased by 15% in the last quarter, leading to missed delivery deadlines.”

Consider the following approaches to refine the problem definition:

- Gather Stakeholder Input: Engage with individuals who are directly affected by the problem. Their insights can help you understand the problem from different perspectives and clarify its scope.

- Analyze Symptoms: Distinguish between symptoms and the actual problem. Symptoms are the observable effects, while the problem is the underlying issue causing these symptoms.

- Document the Problem: Use detailed descriptions, diagrams, or flowcharts to represent the problem. This documentation helps in communicating the issue clearly to others involved in the RCA.

2. Assemble the RCA Team

The success of an RCA largely depends on the expertise and perspectives of the team members involved. Assembling a diverse team ensures a comprehensive analysis and solution development.

When forming your RCA team, consider the following:

- Include Relevant Experts: Select team members who have direct knowledge of the process or system being analyzed. This might include engineers, quality control specialists, or operational staff.

- Ensure Diverse Perspectives: Involve individuals from various departments or functions. Different viewpoints can help uncover aspects of the problem that may not be obvious from a single perspective.

- Designate a Facilitator: Appoint a facilitator to guide the RCA process, manage discussions, and ensure that the analysis stays focused and objective. The facilitator should be neutral and skilled in group dynamics.

Team dynamics play a crucial role in RCA. Encourage open communication and collaboration among team members. Create an environment where everyone feels comfortable sharing their insights and concerns.

3. Gather Data and Evidence

Collecting accurate and relevant data is vital for a thorough RCA. This data provides the foundation for analyzing the problem and identifying root causes.

Follow these steps to gather data effectively:

- Identify Data Sources: Determine where you can obtain the necessary information. This might include system logs, performance reports, incident records, or customer feedback.

- Collect Quantitative and Qualitative Data: Quantitative data involves numerical information, such as production metrics or failure rates. Qualitative data includes non-numeric insights, such as employee observations or customer complaints.

- Verify Data Accuracy: Ensure that the data you collect is accurate and reliable. Cross-check information from different sources to confirm its validity.

- Organize Data: Systematically organize the collected data for easy analysis. Use tools like spreadsheets or databases to categorize and sort the information.

Effective data collection sets the stage for a successful RCA by providing a clear picture of the problem and its context. It enables you to perform a detailed analysis and develop targeted solutions.

RCA Methodologies and Tools

Root Cause Analysis (RCA) employs various methodologies and tools to uncover and address the underlying causes of problems. Understanding these approaches and selecting the appropriate ones for your situation is crucial for effective analysis and problem-solving.

Overview of Different Methodologies

Several methodologies can be used in RCA, each offering a unique approach to identifying and solving issues. Familiarizing yourself with these methods helps you choose the most suitable one for your specific problem.

- Root Cause Tree Analysis: This methodology uses a hierarchical tree diagram to break down a problem into its causes and sub-causes. It helps in visualizing the relationships between different factors and tracking them from the problem back to its root cause.

- Pareto Analysis: Based on the Pareto Principle, this method focuses on identifying the most significant factors that contribute to a problem. It typically involves creating a Pareto Chart, which shows the frequency or impact of problems and helps prioritize which issues to address first.

- Scatter Diagrams: Scatter Diagrams are used to identify relationships between two variables. By plotting data points on a graph, you can observe patterns or correlations that may indicate potential causes of the problem.

- Failure Mode and Effects Analysis (FMEA): FMEA systematically evaluates potential failure modes within a process or product, assessing their effects, and prioritizing them based on risk. This method helps in identifying and mitigating high-risk failure modes before they occur.

- Fault Tree Analysis (FTA): Fault Tree Analysis involves constructing a tree-like diagram to trace the possible causes of system failures. It starts with the top-level failure and works downward to identify all potential causes, helping in understanding complex systems and their failure points.

Qualitative vs. Quantitative Analysis

RCA can involve both qualitative and quantitative analysis, each offering different insights into the problem.

- Qualitative Analysis: This approach focuses on non-numeric data, such as expert opinions, observations, and interviews. Qualitative analysis is useful for understanding the context and human factors behind a problem. It helps in identifying potential causes that may not be immediately apparent through numerical data alone. Techniques like brainstorming sessions and cause-and-effect diagrams are often used in qualitative analysis.

- Quantitative Analysis: Quantitative analysis involves numerical data and statistical methods to analyze problems. It is effective for measuring the magnitude of issues and identifying patterns or correlations. Quantitative techniques include statistical process control, regression analysis, and trend analysis. This approach provides concrete evidence of how variables are related and helps in prioritizing issues based on data-driven insights.

Both qualitative and quantitative analyses complement each other, providing a comprehensive view of the problem. Combining these approaches can lead to a more thorough understanding and more effective solutions.

Commonly Used Tools in RCA

Several tools are commonly used in RCA to facilitate analysis and problem-solving. These tools help in visualizing data, organizing information, and identifying root causes.

- Flowcharts: Flowcharts are diagrams that represent the steps in a process and the relationships between them. They help in mapping out processes to identify where issues occur and how different steps interact. Flowcharts are useful for visualizing workflows and understanding the sequence of events that lead to a problem.

- Fishbone Diagram (Ishikawa Diagram): The Fishbone Diagram categorizes potential causes of a problem into different areas, such as People, Processes, Equipment, and Materials. It helps in organizing and visualizing various factors that contribute to the issue, making it easier to identify root causes.

- Histogram: A Histogram is a type of bar chart that shows the distribution of numerical data. It helps in identifying variations and trends in data, such as defects or errors. By analyzing the frequency of occurrences, you can pinpoint areas that require attention.

- Control Charts: Control Charts monitor process performance over time. They display data points and control limits to track variations and detect anomalies. Control Charts are useful for identifying trends and assessing whether a process is stable or out of control.

- Pareto Chart: A Pareto Chart is a type of bar chart that displays the relative importance of different causes of a problem. Based on the Pareto Principle, it helps in identifying the most significant issues that contribute to the problem, allowing you to prioritize actions.

Each of these tools serves a specific purpose in RCA, and selecting the right tool depends on the nature of the problem and the type of data available. By effectively utilizing these methodologies and tools, you can enhance the accuracy and effectiveness of your Root Cause Analysis.

How to Conduct Root Cause Analysis?

Effectively conducting a Root Cause Analysis (RCA) requires a structured approach to ensure that the analysis identifies the true causes of the problem and leads to actionable solutions. This involves systematically working through each step, analyzing data, distinguishing between symptoms and root causes, and verifying your findings.

To ensure a thorough and effective RCA, follow a structured, step-by-step approach:

- Define the Problem: Clearly articulate the problem you’re addressing. This should include a detailed description of the issue, its impact, and the context in which it occurs.

- Collect Data: Gather all relevant data related to the problem. This includes performance metrics, incident reports, and other pertinent information. Ensure that the data is accurate and representative of the issue.

- Identify Possible Causes: Use tools such as Fishbone Diagrams or brainstorming sessions to list potential causes of the problem. Consider all possible factors that could contribute to the issue.

- Analyze Causes: Review the data and evidence to evaluate each potential cause. Use methodologies like the Five Whys or Fault Tree Analysis to trace the causes back to their origin.

- Determine the Root Cause: From the analyzed data, identify the most likely root cause(s). This involves distinguishing between immediate causes and deeper underlying issues.

- Develop Solutions: Based on the identified root cause(s), create solutions that address the core issue. Ensure that these solutions are practical and can effectively resolve the problem.

- Implement Solutions: Put your solutions into action, making sure that all necessary resources and support are in place.

- Evaluate Results: After implementation, assess the effectiveness of the solutions. Monitor the results to confirm that the problem has been resolved and that no new issues have arisen.

Analyzing Data and Evidence

Analyzing data and evidence is a critical part of RCA. This step involves examining the collected information to identify patterns, trends, and correlations that point to the root cause.

- Organize Data: Systematically arrange the data to make it easier to analyze. Use tools such as spreadsheets or databases to categorize and sort the information.

- Look for Patterns: Identify trends and patterns in the data that may indicate potential causes. For example, frequent equipment failures might correlate with specific operating conditions or time periods.

- Use Statistical Methods: Employ statistical techniques to analyze quantitative data. Methods such as regression analysis or hypothesis testing can help in understanding the relationships between variables and identifying significant factors.

- Cross-Check Data: Verify the accuracy of your data by comparing it with other sources. Inconsistencies or discrepancies may indicate issues with the data collection process or reveal additional insights.

Identifying Root Causes vs. Symptoms

Distinguishing between root causes and symptoms is essential for effective RCA. Symptoms are the observable effects of a problem, while root causes are the underlying issues that lead to these symptoms.

- Recognize Symptoms: Symptoms are the visible problems you observe, such as increased defect rates or equipment breakdowns. While important, they do not provide the full picture of what is causing the issue.

- Trace to Root Causes: Use analytical techniques to trace symptoms back to their root causes. This involves asking “why” multiple times to peel away layers of symptoms and uncover the underlying issues.

- Avoid Quick Fixes: Addressing symptoms with quick fixes may provide temporary relief but will not resolve the underlying problem. Focus on identifying and addressing root causes to prevent recurrence.

Verifying Root Causes

Once you’ve identified potential root causes, it’s crucial to verify that they are indeed the source of the problem. This ensures that your solutions will effectively address the core issue.

- Test Hypotheses: Conduct experiments or simulations to test whether addressing the identified root causes resolves the problem. For example, if you suspect a specific process step is causing defects, modify or eliminate that step and observe the results.

- Seek Confirmation: Consult with experts or stakeholders to confirm that the identified root causes align with their observations and experience. Their insights can provide additional validation or reveal overlooked factors.

- Review Outcomes: Analyze the outcomes of implemented solutions to ensure that they effectively address the root causes. Monitor the problem area to verify that the issue has been resolved and that no new issues have emerged.

Root Cause Analysis Template

Using a structured template for Root Cause Analysis (RCA) helps ensure that all essential steps are followed and that the analysis is thorough and effective. Below is a detailed template you can use for conducting RCA, including sections for defining the problem, analyzing data, identifying root causes, and developing solutions.

Root Cause Analysis Template

1. Problem Statement

Description: Clearly describe the problem you are facing. Include specifics about what, where, when, and how the problem is affecting your operations.

Example:

- Problem: Increase in customer complaints about product defects.

- Details: Over the past three months, there has been a 25% increase in customer complaints regarding defects in the final product, primarily related to incorrect assembly.

2. Data Collection

Data Sources: List all sources of data and evidence collected to understand the problem. Include quantitative and qualitative data.

Data Collected:

- Production logs

- Defect reports

- Customer complaint records

- Inspection reports

3. Identifying Possible Causes

Methodology: Use various RCA techniques (e.g., Fishbone Diagram, Five Whys) to brainstorm and list potential causes of the problem.

Potential Causes:

- Misalignment of assembly equipment

- Inadequate training for assembly staff

- Faulty components from suppliers

- Inefficient quality control processes

4. Analyzing Data

Analysis Techniques: Describe the methods used to analyze the data and identify patterns or correlations.

Analysis Performed:

- Fishbone Diagram: Categorized causes into Equipment, People, Materials, and Processes.

- Five Whys: Traced back from defects to potential underlying issues.

5. Identifying Root Causes

Root Causes: Based on the analysis, list the root causes that are directly contributing to the problem.

Root Causes Identified:

- Equipment misalignment due to inadequate maintenance

- Lack of comprehensive training for assembly staff

- Inconsistent quality control checks

6. Developing Solutions

Action Plan: Outline the proposed solutions to address each root cause. Include specific actions, responsible persons, and deadlines.

Proposed Solutions:

- Equipment Maintenance: Implement a regular maintenance schedule for assembly equipment. Responsible: Maintenance Team. Deadline: 30 days.

- Training Program: Develop and conduct a comprehensive training program for assembly staff. Responsible: HR Department. Deadline: 45 days.

- Quality Control: Revise quality control procedures to include more frequent checks. Responsible: Quality Assurance Team. Deadline: 30 days.

7. Implementing Solutions

Implementation Plan: Detail how the solutions will be put into action. Include steps, resources required, and any support needed.

Implementation Steps:

- Schedule maintenance appointments and ensure all equipment is checked.

- Develop training materials and schedule training sessions for staff.

- Update quality control protocols and train staff on new procedures.

8. Monitoring and Follow-Up

Monitoring Plan: Describe how you will track the effectiveness of the implemented solutions and ensure that the problem is resolved.

Follow-Up Actions:

- Track defect rates and customer complaints post-implementation.

- Conduct follow-up audits to ensure maintenance and training are being adhered to.

- Review and adjust quality control procedures as needed based on performance data.

9. Documentation and Review

Documentation: Record all findings, actions taken, and results of the RCA. This documentation should be reviewed periodically to ensure continuous improvement.

Documented Information:

- RCA process details

- Data and evidence collected

- Root causes and solutions

- Implementation results

Using this template will help you systematically approach Root Cause Analysis, ensuring you address problems effectively and implement lasting solutions. Customize the sections as needed to fit your specific situation and organizational requirements.

Developing and Implementing Solutions

Once you’ve identified and verified the root causes, the next step is to develop and implement effective solutions. This involves creating actionable plans, prioritizing interventions, and monitoring their impact.

1. Create Action Plans

Developing a detailed action plan is essential for addressing the root causes identified during the RCA. The plan should outline the steps required to implement solutions and resolve the problem.

- Define Actions: Clearly specify the actions that need to be taken to address the root causes. These actions should be practical and achievable.

- Assign Responsibilities: Designate individuals or teams responsible for carrying out each action. Ensure that they have the necessary resources and authority to implement the changes.

- Set Timelines: Establish realistic deadlines for each action. This helps in tracking progress and ensures that solutions are implemented in a timely manner.

- Allocate Resources: Identify the resources needed for implementation, such as budget, personnel, or equipment. Ensure that these resources are available and allocated appropriately.

2. Prioritize Solutions

Not all solutions will have the same impact or feasibility. Prioritizing solutions helps focus efforts on the most significant issues first.

- Evaluate Impact: Assess the potential impact of each solution on the problem. Prioritize solutions that address the most critical root causes and offer the greatest benefits.

- Consider Feasibility: Evaluate the feasibility of each solution based on factors such as cost, complexity, and resource requirements. Prioritize solutions that are practical and achievable within the given constraints.

- Create a Priority List: Develop a list of solutions in order of priority, focusing first on those that offer the highest impact and are most feasible to implement.

3. Implement Changes

Effective implementation of solutions is key to resolving the problem and preventing recurrence.

- Communicate Changes: Clearly communicate the planned changes to all relevant stakeholders. Ensure that everyone involved understands their roles and responsibilities in the implementation process.

- Execute the Plan: Carry out the actions outlined in your action plan. Monitor progress closely to ensure that changes are implemented as planned.

- Address Issues: Be prepared to address any issues or challenges that arise during implementation. Flexibility and problem-solving skills are crucial to overcoming obstacles and ensuring successful execution.

4. Monitor and Follow Up

After implementing solutions, ongoing monitoring and follow-up are essential to ensure that the problem has been resolved and to identify any potential new issues.

- Track Results: Continuously monitor the area where changes were made to assess the effectiveness of the solutions. Use performance metrics and feedback to gauge success.

- Conduct Reviews: Regularly review the outcomes and impact of the implemented solutions. Check for any signs of recurring issues or new problems that may need attention.

- Adjust as Needed: Be prepared to make adjustments based on monitoring results and feedback. Continuous improvement is key to maintaining effectiveness and addressing any evolving issues.

By carefully developing and implementing solutions, you can effectively address the root causes of problems and achieve lasting improvements.

Root Cause Analysis Examples

Understanding how Root Cause Analysis (RCA) works can be much easier with real-world examples. By examining various scenarios where RCA has been applied, you can see how different methodologies and tools come into play to address and resolve problems. Here are a few detailed examples demonstrating how RCA can be used in various contexts:

Example 1: Manufacturing Defects

Scenario: A manufacturing company notices a rise in defective products coming off their production line. The defects include misaligned parts and uneven finishes.

RCA Process:

- Define the Problem: The problem is an increase in defective products, specifically misalignment and uneven finishes.

- Collect Data: Gather data on production processes, defect rates, machine calibration records, and operator logs.

- Identify Possible Causes: Use brainstorming and Fishbone Diagrams to list potential causes, such as misaligned machinery, faulty components, or inadequate training.

- Analyze Causes: Perform a root cause analysis using the Five Whys technique. For example:

- Why are the products defective? → Because parts are misaligned.

- Why are parts misaligned? → Because the machine is not calibrated correctly.

- Why is the machine not calibrated? → Because the calibration schedule was not followed.

- Why was the calibration schedule not followed? → Because of a lack of reminders and process adherence.

- Determine Root Causes: The root causes identified include insufficient reminders for calibration schedules and lack of adherence to maintenance protocols.

- Develop Solutions: Implement a regular calibration schedule with automated reminders and establish a checklist to ensure adherence.

- Verify Solutions: Monitor the defect rate after implementing the solutions. The number of defects should decrease, indicating that the root causes have been addressed.

Example 2: Customer Service Complaints

Scenario: A company receives numerous complaints from customers about long wait times when contacting customer service.

RCA Process:

- Define the Problem: The problem is long customer service wait times.

- Collect Data: Review call logs, customer feedback, and service staff schedules.

- Identify Possible Causes: Create a Fishbone Diagram to explore causes like understaffing, inefficient call routing, or outdated technology.

- Analyze Causes: Use Pareto Analysis to determine the most significant contributing factors. For example:

- Analyze call volume patterns and staff availability to find peaks in demand that align with longer wait times.

- Review call routing data to identify inefficiencies.

- Determine Root Causes: The root causes include insufficient staff during peak hours and outdated call routing technology.

- Develop Solutions: Hire additional staff for peak hours and upgrade to a more efficient call routing system.

- Verify Solutions: After implementing these changes, track wait times and customer satisfaction scores to ensure improvements are effective.

Example 3: IT System Downtime

Scenario: An organization experiences frequent IT system downtimes, disrupting daily operations and causing frustration among employees.

RCA Process:

- Define the Problem: Frequent IT system downtimes affecting operations.

- Collect Data: Gather data on system logs, downtime occurrences, maintenance records, and error reports.

- Identify Possible Causes: Use Fault Tree Analysis to list potential causes such as hardware failures, software bugs, or inadequate system maintenance.

- Analyze Causes: Apply the Five Whys technique to investigate:

- Why is the system down? → Because of server crashes.

- Why are servers crashing? → Because of overheating.

- Why is overheating occurring? → Because cooling systems are malfunctioning.

- Why are cooling systems malfunctioning? → Because of a lack of regular maintenance.

- Determine Root Causes: The root causes are identified as inadequate maintenance of cooling systems and failure to address early warning signs.

- Develop Solutions: Schedule regular maintenance for cooling systems and implement monitoring tools to detect overheating early.

- Verify Solutions: Monitor system performance and downtime frequency to confirm that the changes have resolved the underlying issues.

These examples illustrate how Root Cause Analysis can be applied to various situations to uncover and address the fundamental issues affecting performance. By following a systematic approach, you can effectively resolve problems and prevent their recurrence.

Root Cause Analysis Best Practices

Adhering to best practices in Root Cause Analysis (RCA) ensures that your approach is thorough, effective, and results in sustainable improvements. Here’s a comprehensive list of best practices to follow:

- Clearly Define the Problem: Start with a precise and detailed problem statement to ensure that the analysis focuses on the right issue.

- Assemble a Diverse Team: Include individuals with different perspectives and expertise to enhance the analysis and solution development.

- Collect Accurate Data: Gather relevant and accurate data from reliable sources to provide a solid foundation for your analysis.

- Use Multiple Methodologies: Employ a combination of RCA methodologies and tools to get a comprehensive understanding of the problem.

- Differentiate Between Symptoms and Root Causes: Focus on identifying and addressing the underlying causes rather than just treating the symptoms.

- Verify Root Causes: Test and validate identified root causes to ensure that they are the true source of the problem.

- Develop Detailed Action Plans: Create actionable, clear, and realistic plans for implementing solutions, including timelines and assigned responsibilities.

- Prioritize Solutions: Assess and prioritize solutions based on their potential impact and feasibility to address the most critical issues first.

- Communicate Effectively: Ensure that all stakeholders are informed about changes and understand their roles in the implementation process.

- Monitor and Review: Continuously track the effectiveness of implemented solutions and make necessary adjustments based on ongoing feedback and performance metrics.

- Document the Process: Keep detailed records of the RCA process, including data, findings, actions taken, and outcomes. This documentation aids in future analyses and helps in institutional learning.

- Encourage a Culture of Continuous Improvement: Foster an environment where feedback is actively sought and used for ongoing improvements, and where learning from RCA is integrated into everyday practices.

By following these best practices, you can enhance the effectiveness of your Root Cause Analysis and drive meaningful, long-term improvements.

Conclusion

Root Cause Analysis (RCA) is more than just a method for solving problems—it’s a crucial approach for ensuring long-term success and improvement in any organization or process. By systematically identifying and addressing the underlying causes of issues, RCA helps you avoid temporary fixes and instead fosters sustainable solutions. This guide has explored various RCA methodologies, tools, and best practices that can help you thoroughly understand and resolve problems. With these insights, you can enhance efficiency, improve quality, and reduce costs, all while building a proactive culture of continuous improvement.

As you apply the principles of RCA, remember that effective problem-solving involves not only identifying root causes but also implementing and verifying solutions. Regularly revisiting and refining your processes based on RCA findings will keep you ahead of recurring issues and drive meaningful progress. Embracing RCA as a regular part of your problem-solving toolkit will not only help address current challenges but also prepare you to tackle future ones with greater confidence and clarity.

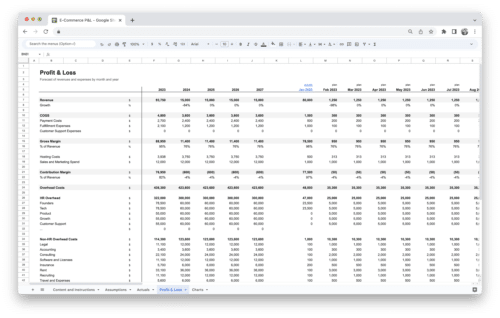

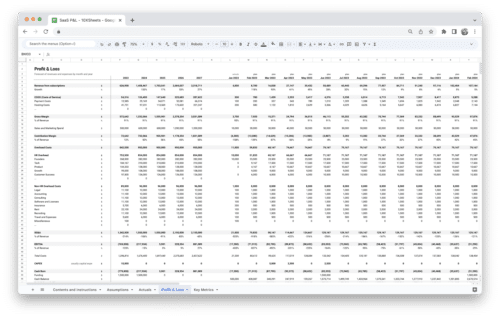

Get Started With a Prebuilt Template!

Looking to streamline your business financial modeling process with a prebuilt customizable template? Say goodbye to the hassle of building a financial model from scratch and get started right away with one of our premium templates.

- Save time with no need to create a financial model from scratch.

- Reduce errors with prebuilt formulas and calculations.

- Customize to your needs by adding/deleting sections and adjusting formulas.

- Automatically calculate key metrics for valuable insights.

- Make informed decisions about your strategy and goals with a clear picture of your business performance and financial health.

-

Sale!

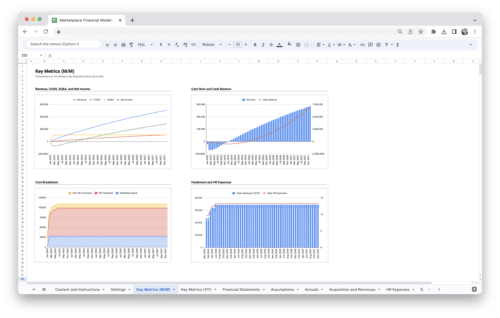

Marketplace Financial Model Template

Original price was: $219.00.$149.00Current price is: $149.00. Add to Cart -

Sale!

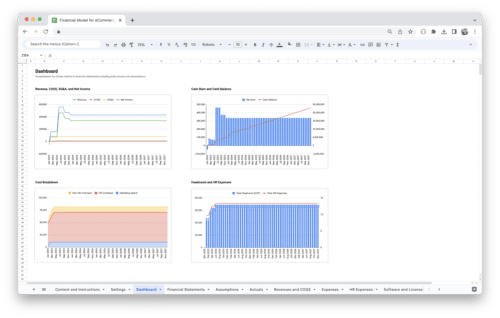

E-Commerce Financial Model Template

Original price was: $219.00.$149.00Current price is: $149.00. Add to Cart -

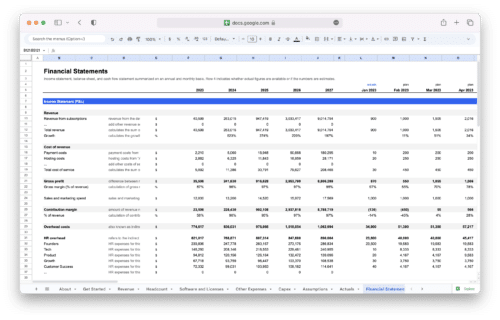

Sale!

SaaS Financial Model Template

Original price was: $219.00.$149.00Current price is: $149.00. Add to Cart -

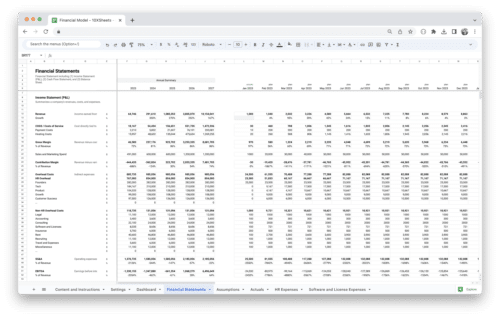

Sale!

Standard Financial Model Template

Original price was: $219.00.$149.00Current price is: $149.00. Add to Cart -

Sale!

E-Commerce Profit and Loss Statement

Original price was: $119.00.$79.00Current price is: $79.00. Add to Cart -

Sale!

SaaS Profit and Loss Statement

Original price was: $119.00.$79.00Current price is: $79.00. Add to Cart