Are you looking for a way to streamline your manufacturing processes and improve efficiency? MRP (Material Requirements Planning) software could be the solution you need. This powerful tool helps businesses manage everything from inventory and production schedules to procurement and supply chain management. With the right MRP software, you can ensure that you have the right materials at the right time, reduce waste, and keep your production running smoothly.

There are many options available, each offering unique features tailored to different business needs. Whether you’re a small business looking for an affordable solution or a large enterprise needing advanced capabilities, this guide will help you find the best MRP software to suit your operations.

What is MRP Software?

Material Requirements Planning (MRP) software is a specialized tool used by manufacturers to manage and optimize their production processes. It helps businesses plan the procurement of materials, schedule production, and manage inventory, ensuring that the right materials are available at the right time without overstocking or running into shortages. MRP software integrates with other business systems, such as Enterprise Resource Planning (ERP), to provide a seamless flow of data across the organization, improving overall efficiency.

At its core, MRP software calculates the materials required for production based on demand forecasts, current inventory levels, and the Bill of Materials (BOM). It then generates purchase orders and production schedules, helping companies maintain smooth operations while avoiding costly disruptions. By automating many aspects of the supply chain and production planning, MRP software allows businesses to focus more on meeting customer demand and driving growth.

Importance of MRP Software in Modern Manufacturing

As manufacturing processes become increasingly complex, businesses need to rely on advanced technology to stay competitive. MRP software plays a critical role in modern manufacturing by addressing the following challenges:

- Efficiency: MRP software streamlines inventory management, procurement, and production scheduling, reducing the time spent on manual tasks and preventing production delays.

- Cost Control: By accurately forecasting demand and optimizing material usage, MRP software helps reduce excess inventory, minimize waste, and cut down on operational costs.

- Improved Decision-Making: With real-time data and reporting capabilities, MRP software enables managers to make informed decisions that improve production efficiency and reduce bottlenecks.

- Scalability: As your business grows, MRP software can scale to handle larger inventories, more complex manufacturing processes, and increased production demands.

- Supply Chain Optimization: MRP software ensures that materials are available when needed, allowing for smoother supply chain operations and reducing the risk of stockouts or delayed shipments.

Benefits of Using MRP Software for Businesses

Adopting MRP software brings significant advantages for manufacturers of all sizes. These benefits are designed to improve productivity, reduce waste, and enhance the overall efficiency of manufacturing operations. Here’s a look at some of the key benefits of using MRP software:

- Better Inventory Control: MRP software helps businesses keep track of their inventory in real-time, ensuring that materials are available for production without overstocking or running into shortages.

- Optimized Production Scheduling: By aligning production schedules with material availability, MRP software minimizes downtime and ensures that manufacturing runs as smoothly as possible.

- Enhanced Demand Forecasting: Accurate demand forecasts allow businesses to better plan their procurement and production schedules, reducing the risk of overstocking or understocking.

- Improved Supplier Management: MRP software allows businesses to automate purchase orders and monitor supplier performance, reducing the risk of delays and ensuring timely delivery of materials.

- Cost Savings: By minimizing waste and optimizing material usage, MRP software helps businesses cut costs, ultimately improving their bottom line.

- Increased Productivity: With automated processes and streamlined workflows, MRP software frees up employees to focus on more strategic tasks, enhancing overall productivity.

- Greater Compliance: MRP software helps ensure that manufacturing processes meet regulatory standards and industry-specific requirements, reducing the risk of compliance issues.

- Real-Time Reporting and Analytics: MRP systems offer valuable insights into production processes, inventory levels, and supplier performance, helping businesses make data-driven decisions.

Top MRP Software Solutions

Choosing the right MRP software solution can make all the difference in optimizing your manufacturing operations. With many options available on the market, it’s important to select a tool that best meets the specific needs of your business. Below are some of the leading MRP software solutions that stand out in the industry, known for their reliability, scalability, and powerful features.

SAP Business One

SAP Business One is one of the most popular MRP solutions for small and medium-sized enterprises (SMEs). As part of the SAP family, this software offers an integrated approach to business management, including production planning, inventory management, and financial reporting. SAP Business One helps businesses streamline operations by providing real-time insights into materials, stock levels, and production schedules. Its robust set of tools covers everything from order management to procurement, allowing businesses to optimize their supply chain while improving overall efficiency. Additionally, it integrates seamlessly with other SAP solutions, making it a great choice for companies that need a comprehensive enterprise resource planning (ERP) system.

Oracle NetSuite

Oracle NetSuite is another top contender in the MRP software market, offering a cloud-based solution that is widely favored by growing businesses. This scalable MRP tool integrates seamlessly with Oracle’s ERP suite, providing end-to-end visibility into manufacturing processes. NetSuite allows businesses to manage inventory, plan production schedules, and automate procurement all in one place. Its advanced demand forecasting and real-time data capabilities enable businesses to reduce waste and ensure that materials are available when needed. With features that cater to various industries, including wholesale distribution, retail, and manufacturing, Oracle NetSuite is a great choice for businesses looking for a flexible, cloud-based MRP system with advanced reporting tools.

Plex Systems

Plex Systems offers a cloud-based MRP solution that is particularly well-suited for manufacturers in industries such as automotive, aerospace, and electronics. It stands out with its real-time data capabilities, helping businesses track production processes and inventory levels instantaneously. Plex Systems offers robust features for supply chain management, quality control, and production planning. One of its key strengths is its ability to manage both shop floor operations and supply chain logistics in a single platform, providing greater visibility into the entire manufacturing process. With its user-friendly interface and powerful analytics tools, Plex is an excellent choice for manufacturers seeking a scalable, cloud-based solution with comprehensive capabilities.

Syspro

Syspro is a versatile MRP software solution that offers deep customization options for manufacturers. Designed for small to mid-sized businesses, Syspro’s modular architecture allows users to pick and choose the features they need, making it an ideal choice for companies with unique manufacturing processes. With Syspro, businesses can manage inventory, production schedules, and procurement in one place, all while benefiting from advanced reporting and analytics tools. The software is known for its ease of use and flexibility, allowing businesses to adapt the system to their specific requirements. Syspro also offers strong integration capabilities, making it a great option for businesses that need a tailored solution that can integrate with existing systems.

Odoo

Odoo is an open-source ERP system that includes powerful MRP capabilities, making it a great option for businesses looking for an affordable and customizable solution. Odoo’s MRP features include inventory management, production planning, and procurement automation, all of which can be tailored to the specific needs of your business. The software’s modular nature allows businesses to add other functionalities as needed, such as accounting, customer relationship management (CRM), and sales management. Odoo’s flexibility makes it an excellent choice for small to mid-sized businesses that need an adaptable MRP solution that can grow with them. With an active open-source community, businesses can also take advantage of custom modules and updates to keep their system current.

Fishbowl Manufacturing

Fishbowl Manufacturing is a leading MRP solution designed for small to mid-sized manufacturers. It provides comprehensive inventory management, production scheduling, and order fulfillment features, making it a popular choice for companies looking to streamline operations. Fishbowl Manufacturing integrates with popular accounting software like QuickBooks, allowing businesses to manage both financial and production operations seamlessly. The software’s intuitive interface and easy implementation make it a great option for businesses that want to implement MRP software without a lengthy learning curve. Fishbowl also offers robust tracking and reporting features, helping businesses stay on top of production progress and inventory levels.

Microsoft Dynamics 365 Finance

Microsoft Dynamics 365 for Finance and Operations is a powerful ERP and MRP solution designed for larger businesses and enterprises. It offers comprehensive tools for managing supply chains, production planning, procurement, and inventory management. As part of the broader Microsoft ecosystem, Dynamics 365 seamlessly integrates with other Microsoft tools like Office 365, Power BI, and Azure, making it ideal for businesses already using these products. With its robust analytics and reporting capabilities, businesses can track real-time production data and make informed decisions about supply chain and inventory management.

Infor CloudSuite Industrial

Infor CloudSuite Industrial (SyteLine) is a cloud-based ERP and MRP solution designed for manufacturers of all sizes. It offers industry-specific tools for managing production, inventory, and supply chains. SyteLine is known for its deep functionality, particularly for manufacturers in industries like automotive, aerospace, and industrial machinery. The software includes advanced tools for production planning, material requirement forecasting, and demand management. Additionally, Infor CloudSuite’s cloud-based architecture allows businesses to scale easily, while its robust reporting and analytics tools provide actionable insights into production processes.

Acumatica Cloud ERP

Acumatica Cloud ERP is a versatile MRP solution that provides manufacturers with powerful tools for inventory management, production scheduling, and supply chain management. Acumatica stands out for its user-friendly interface and flexible cloud-based architecture. The software allows businesses to manage materials, track production orders, and forecast demand. Acumatica’s integration with other business systems, such as CRM and financial management, helps ensure a seamless flow of data across the organization. Its scalability and customization options make it suitable for businesses of all sizes, from small manufacturers to large enterprises.

Priority Software

Priority Software is a comprehensive ERP and MRP system that caters to businesses in a variety of industries, including manufacturing, retail, and distribution. Its MRP capabilities include advanced planning and scheduling, inventory control, and procurement management. Priority Software offers both on-premise and cloud-based deployment options, providing flexibility for businesses that need either solution. The system also includes powerful reporting tools, allowing businesses to monitor production performance and adjust schedules in real-time. With its modular design, Priority Software is highly customizable, making it a great choice for businesses with specific manufacturing needs.

Exact Macola

Exact Macola is a comprehensive MRP and ERP solution that offers robust tools for managing manufacturing processes, from inventory and production planning to procurement and supply chain management. Known for its user-friendly interface and scalability, Exact Macola is ideal for small to mid-sized manufacturers looking for an affordable yet powerful MRP solution. The software allows businesses to automate processes, reduce manual errors, and improve production scheduling. Exact Macola’s cloud-based option makes it easy to scale as your business grows, while its advanced reporting features provide deep insights into production and inventory data.

JustFood Bakery Software

JustFood Bakery Software is an industry-specific MRP solution designed for bakeries and food manufacturers. It includes all the essential MRP features such as inventory management, production planning, demand forecasting, and procurement. The software is tailored to meet the unique challenges faced by food manufacturers, including tracking perishable goods, managing batch production, and adhering to regulatory compliance standards. JustFood Bakery Software offers a streamlined user experience, allowing businesses in the food industry to manage their operations more efficiently and improve traceability from raw materials to finished products.

Ramco ERP on Cloud

Ramco ERP on Cloud is a cloud-based ERP solution with comprehensive MRP features designed to cater to global manufacturers. It provides businesses with tools for production planning, inventory management, and supply chain management. The software stands out for its scalability and flexibility, making it suitable for both small manufacturers and large enterprises with complex needs. Ramco ERP includes advanced analytics and reporting features, giving businesses the ability to monitor production performance and optimize supply chain operations in real time. Its cloud-based platform ensures that businesses can access their data anytime, anywhere, facilitating better decision-making.

VAI S2K Enterprise

VAI S2K Enterprise is a robust ERP and MRP system tailored to manufacturers across a wide range of industries. The software provides comprehensive tools for inventory management, production planning, and order processing. VAI S2K Enterprise offers both on-premise and cloud-based deployment options, providing flexibility for businesses of all sizes. It also includes advanced reporting tools that give businesses visibility into their supply chain, production processes, and inventory levels. The software’s scalability allows it to grow with businesses as their needs evolve, while its industry-specific functionality ensures that manufacturers have the tools they need to optimize their operations.

These top MRP software solutions are designed to help businesses of various sizes and industries optimize their manufacturing processes. From inventory management to production planning and demand forecasting, each of these tools provides powerful features to streamline operations and improve efficiency. Selecting the right MRP system will depend on your company’s specific needs, budget, and future growth plans, but these options represent some of the best tools available on the market today.

MRP Software Features to Look For

MRP software comes packed with features that help manufacturers plan, track, and manage every stage of the production process. Understanding these key features will allow you to make an informed decision when choosing the best solution for your business. Let’s take a closer look at the features that are essential to optimizing your manufacturing operations.

Inventory Management

One of the most crucial aspects of MRP software is inventory management. This feature helps you maintain precise control over the materials and products in your warehouse. Whether it’s raw materials, work-in-progress goods, or finished products, MRP software allows you to track inventory in real time. With real-time data on stock levels, you can avoid both overstocking and stockouts, ensuring that production is always on track.

The software can also automate reorder points based on predefined thresholds, reducing the manual effort needed to monitor inventory. Furthermore, integration with barcode scanning or RFID technology can make inventory tracking even more accurate, reducing human error and ensuring that inventory data is always up to date.

Demand Forecasting and Production Planning

Accurate demand forecasting is essential for making sure you have enough materials without holding excess stock. MRP software uses historical sales data, market trends, and other variables to predict future demand for finished goods. With this insight, you can adjust production plans accordingly, making sure that production schedules align with actual demand.

Using these forecasts, MRP software helps plan the procurement of raw materials and components ahead of time, ensuring they are available when needed without delays. This reduces production downtime and ensures that your operations run smoothly. Moreover, it helps prevent the chaos that can arise when there is too much or too little stock on hand, streamlining your production process.

Bill of Materials (BOM) Management

A Bill of Materials (BOM) is a detailed inventory list of all raw materials, sub-assemblies, and components required to manufacture a product. Managing BOMs can become complicated, especially in industries with complex product designs and large inventories. MRP software simplifies this by centralizing BOM data, enabling you to easily track changes, revisions, and materials needed for production.

With the right MRP software, you can manage multiple levels of BOMs, allowing for the creation of complex product assemblies and sub-assemblies. Additionally, BOMs can be linked with inventory data, meaning that the software can alert you if any components are out of stock, helping you avoid production delays. This level of integration ensures that you always have the necessary parts to keep your production on schedule.

Supplier Management and Purchase Order Automation

Efficient supplier management is vital to the smooth running of manufacturing operations. MRP software allows you to maintain a centralized database of all your suppliers, including contact details, pricing, lead times, and historical performance. This enables you to build stronger relationships with suppliers and negotiate better terms.

Another key benefit is the automation of purchase orders. MRP systems can automatically generate purchase orders based on real-time inventory data, taking into account lead times, stock levels, and demand forecasts. This reduces the need for manual intervention, ensuring that materials are ordered automatically as soon as stock levels reach predetermined thresholds. This feature reduces human error, saves time, and prevents materials from running out, which can halt production.

Real-Time Data and Reporting

Real-time data and reporting are essential for making informed, data-driven decisions. With MRP software, you gain access to real-time updates on everything from inventory levels to production progress, helping you stay ahead of potential problems before they arise.

Advanced reporting tools can generate detailed reports that show not only the current status of your manufacturing processes but also historical trends. These insights are invaluable for decision-making, whether you’re assessing your supply chain efficiency, identifying bottlenecks in production, or evaluating vendor performance. With this data at your fingertips, you can make proactive adjustments that enhance efficiency and reduce costs.

Integration with Other Business Systems (ERP, CRM)

For any manufacturing business, the ability to integrate different software tools is essential. MRP systems that integrate with your Enterprise Resource Planning (ERP) system, Customer Relationship Management (CRM) software, and accounting systems provide a seamless flow of data across your business operations.

Integration with ERP systems allows your MRP software to synchronize inventory management, procurement, and production planning with other key business functions, like finance and sales. This ensures that every department has access to the same up-to-date information, reducing the risk of errors and delays caused by disconnected systems. Additionally, integrating with CRM tools helps sales and marketing teams align with production schedules, ensuring that customer demand is met without overstretching production capabilities.

By connecting all the key functions of your business, MRP software becomes the backbone of your operational infrastructure, enabling smarter decision-making and improving overall efficiency.

Types of MRP Software

When it comes to selecting MRP software for your business, it’s important to understand the different types available. Each type of MRP software offers distinct advantages, and the best choice for your company will depend on your specific needs, size, and operational requirements. Let’s explore the four primary types of MRP software and how they can impact your manufacturing processes.

Traditional MRP Systems

Traditional MRP systems are often on-premise software solutions that have been around for decades. These systems offer a comprehensive suite of tools designed to manage production planning, inventory control, and procurement processes. They are typically best suited for large businesses with complex, customized manufacturing needs.

One of the primary benefits of traditional MRP systems is their ability to be highly customized to meet the specific needs of a business. If your manufacturing operations require intricate workflows, detailed bill of materials (BOM) management, or unique reporting capabilities, traditional MRP systems can be tailored to fit those requirements. However, this level of customization often comes with a steep learning curve and substantial upfront costs.

Traditional systems are usually installed and hosted on your company’s own servers, which gives you complete control over the software and data. This can be an advantage for companies that need to keep sensitive data on-premise for security or compliance reasons. The downside is that maintaining these systems can be costly, as they require regular updates, security patches, and in-house IT support.

While these systems were once the go-to choice for large manufacturers, the industry has increasingly shifted toward cloud-based solutions due to the growing demand for flexibility, scalability, and lower maintenance costs.

Cloud-Based MRP Software

Cloud-based MRP software has rapidly gained popularity, especially among small to medium-sized businesses. Unlike traditional on-premise systems, cloud-based MRP software is hosted on remote servers and accessed via the internet, offering several key advantages.

One of the biggest benefits of cloud-based MRP software is its scalability. As your business grows, cloud solutions can easily expand to accommodate increasing production volumes, inventory, and data storage needs. You don’t have to worry about purchasing additional servers or maintaining complex IT infrastructure—everything is handled by the software provider. This makes cloud-based MRP a more affordable option, particularly for companies that want to avoid large upfront investments.

Additionally, cloud-based MRP systems allow you to access your data from anywhere with an internet connection, making them ideal for businesses with multiple locations or remote teams. Real-time updates and collaborative features enable cross-functional teams to stay in sync, improving decision-making and operational efficiency.

The downside to cloud-based MRP is that it relies on internet connectivity, so if your network experiences downtime, access to your data could be temporarily disrupted. However, many providers offer backup systems to minimize this risk. Another consideration is security, as data is hosted off-site, so it’s important to choose a vendor with strong security measures and compliance certifications.

Hybrid Solutions: On-Premise and Cloud Combination

Hybrid MRP solutions combine the best of both traditional on-premise systems and cloud-based systems. These solutions allow businesses to host some parts of their MRP software on-premise, while others are hosted in the cloud. Hybrid MRP is ideal for companies that require a mix of control, customization, and flexibility.

For example, a business might choose to keep sensitive data and core business processes on-premise while using cloud-based solutions for non-sensitive functions like order processing, inventory management, or analytics. This approach allows you to maintain more control over certain aspects of your manufacturing process while still benefiting from the flexibility and scalability of the cloud.

Hybrid solutions offer the advantage of adaptability. If you have stringent compliance or security requirements that necessitate on-premise hosting for certain data, a hybrid solution can accommodate those needs while offering cloud-based tools for other parts of your operations. It also makes it easier to transition from traditional on-premise systems to cloud-based solutions over time, as you can migrate specific functions gradually.

However, hybrid systems can be more complex to manage due to the need for integrating both on-premise and cloud-based components. You’ll need a strong IT infrastructure to ensure smooth operation between the two systems. While hybrid MRP offers flexibility, it may require additional resources to ensure everything works seamlessly.

Industry-Specific MRP Solutions

Some MRP software solutions are designed specifically for particular industries, and these solutions offer features tailored to meet the unique needs of that sector. Industry-specific MRP solutions are becoming increasingly popular, as they provide specialized tools that go beyond the core functionality of traditional MRP systems.

For example, industries such as automotive, electronics, and food manufacturing have specific regulatory, operational, and compliance requirements that standard MRP systems may not address effectively. Industry-specific MRP software is designed to handle these unique challenges with built-in features like compliance tracking, quality control, traceability, and specialized reporting.

In addition to compliance and regulatory benefits, industry-specific MRP systems often offer workflows that are optimized for particular manufacturing processes. For instance, a food manufacturer may need advanced tracking for perishable items, while an automotive manufacturer may require specialized BOM management for complex, multi-tiered assemblies.

While industry-specific MRP solutions provide significant advantages in terms of meeting sector-specific demands, they also tend to be more expensive and less flexible than generic MRP systems. Customization can be limited, and switching to a different system in the future might require a more significant investment in time and resources.

Choosing an industry-specific MRP solution makes sense for businesses with complex, industry-specific needs. However, smaller businesses or those without highly specialized requirements may find that a more general-purpose MRP system can deliver sufficient functionality at a lower cost.

Each type of MRP software comes with its own set of advantages and considerations. Traditional systems offer robust functionality but come with high costs and maintenance needs. Cloud-based solutions provide scalability and flexibility, making them ideal for businesses looking to modernize their operations. Hybrid solutions offer the best of both worlds, while industry-specific MRP software is perfect for companies with unique manufacturing needs. The right choice depends on your business size, industry, and specific goals, so it’s essential to weigh the pros and cons carefully before making your decision.

How to Choose the Best MRP Software?

Choosing the right MRP software can be a daunting task, especially with so many options available on the market. The best solution for your business will depend on various factors, such as your company’s size, industry, and specific operational requirements. To help guide your decision, there are several key considerations you should take into account. Let’s dive into the critical factors that will help you choose the MRP software that’s right for your business.

Considerations Based on Company Size and Needs

One of the first things to consider when selecting MRP software is your company size and operational complexity. Different MRP systems cater to businesses of varying sizes, and it’s essential to match your needs with the software’s capabilities.

For small and medium-sized businesses (SMBs), simplicity and cost-effectiveness are typically the top priorities. SMBs often need a solution that is quick to implement, easy to use, and affordable. Cloud-based MRP software tends to be an excellent fit for these businesses because it offers scalability without the burden of heavy upfront costs or IT infrastructure.

On the other hand, large enterprises with more complex manufacturing processes may require a more robust, customizable MRP system. These companies often need specialized features such as multi-location support, advanced reporting, and deeper integration with other enterprise systems (like ERP and CRM). If your business operates on a global scale or has multiple production sites, you’ll need an MRP system that can handle large volumes of data and offer in-depth customization to accommodate your unique needs.

Understanding your company’s size and manufacturing complexity will help narrow down the field and ensure that you’re selecting an MRP solution that’s a good fit for your operations.

Scalability and Customization Options

Scalability and customization are two critical features to consider when evaluating MRP software. As your business grows, your needs will inevitably evolve, and your software solution should be able to keep up with these changes.

Scalability ensures that your MRP system can handle increased production volumes, larger inventories, and expanded production lines as your business expands. For instance, cloud-based solutions are often highly scalable, allowing you to add more users, integrate new features, or expand to additional locations without significant disruption to your operations.

Customization is equally important, especially for businesses with unique or complex manufacturing processes. Some MRP systems allow you to tailor workflows, create custom reports, and modify the user interface to meet your specific requirements. Customizable MRP software ensures that the system can be fine-tuned to align perfectly with how your business operates, rather than forcing you to adapt your processes to fit the software.

Choosing an MRP solution with both scalability and customization ensures that you won’t outgrow the system too quickly and that it will continue to meet your evolving needs.

Integration Capabilities with Existing Systems

An MRP system that seamlessly integrates with your existing systems is essential for maximizing efficiency and minimizing manual data entry. In today’s connected world, MRP software doesn’t operate in isolation—it should communicate with other business systems, such as Enterprise Resource Planning (ERP), Customer Relationship Management (CRM), and accounting software.

Integration capabilities vary greatly from one MRP solution to another. Some systems are designed to work out of the box with popular ERP platforms, while others may require additional setup or third-party integration tools. Before selecting an MRP system, it’s important to ensure that it can integrate smoothly with the systems you already use. This ensures that data flows seamlessly between departments, reducing errors and increasing overall efficiency.

For example, when an order is placed in your CRM, the MRP system should automatically receive the relevant data to adjust inventory levels and schedule production. This integration eliminates the need for manual data transfer and ensures that all teams are working with the most up-to-date information.

Be sure to check the integration options and compatibility with your existing software to ensure that your new MRP system can support your current workflows without creating bottlenecks or requiring excessive customization.

Ease of Use and User Interface Design

The ease of use and the user interface (UI) design are often overlooked but are critical factors in the success of an MRP system. If the software is difficult to navigate or requires extensive training, your team may resist adopting it, and the system may fail to live up to its potential.

Look for an MRP system with an intuitive, user-friendly interface that allows your team to quickly grasp how to use it. An easy-to-navigate system will reduce training time and minimize errors, leading to a smoother transition and quicker return on investment.

Consider how the MRP software presents data and whether the interface is customizable to meet your team’s needs. Some systems offer dashboards or customizable workspaces, so users can prioritize the information they need most. The more user-friendly the system, the faster your team will get up to speed and start using the software effectively.

The user interface should also be visually appealing and well-organized, making it easier for your team to perform tasks such as entering orders, managing inventory, or generating reports. If possible, request a demo or trial period to evaluate the software’s user-friendliness before making a commitment.

Customer Support and Training Resources

Even the best MRP software will encounter challenges or require fine-tuning as you use it. That’s why customer support and training resources are essential considerations when selecting a software provider. Reliable support ensures that any issues that arise can be resolved quickly, minimizing downtime and disruptions to your business operations.

When evaluating MRP software providers, check the level of customer support they offer. Look for vendors who provide multiple support channels, including live chat, email, phone support, and a comprehensive knowledge base. It’s also helpful to consider whether the provider offers dedicated account managers or customer success teams that can assist with troubleshooting and system optimization.

Training resources are equally important. A good vendor will offer tutorials, guides, and training sessions to help your team get the most out of the software. This can include on-demand videos, documentation, and live webinars. For larger businesses or those transitioning to MRP software for the first time, in-person or virtual training sessions can help ensure that your staff is fully equipped to use the system effectively.

Before making a final decision, be sure to evaluate the support and training options available to ensure that your team will be well-supported throughout the entire process of implementation and beyond.

Choosing the right MRP software is a decision that will have a significant impact on the efficiency and effectiveness of your manufacturing operations. By considering factors like company size, scalability, integration capabilities, user-friendliness, and customer support, you can ensure that the solution you choose will meet your business’s current and future needs. Taking the time to evaluate these considerations carefully will set you up for long-term success and help you make the most out of your investment in MRP technology.

MRP Software Use Cases

MRP software is versatile and can be applied across various manufacturing industries to solve a wide range of operational challenges. Below are some of the key use cases where MRP software can bring significant value to your business:

- Streamlining production processes: MRP software helps businesses optimize their production schedules by ensuring that materials are available when needed, reducing downtime and improving overall efficiency.

- Inventory control and stock optimization: By providing real-time data on stock levels, MRP software helps prevent overstocking or stockouts, ensuring that materials are always on hand for production without tying up unnecessary capital in excess inventory.

- Improved demand forecasting: With accurate demand forecasting, manufacturers can better plan their production runs, ensuring they meet customer demand without excessive lead times or delays.

- Enhancing procurement efficiency: MRP systems automate the purchasing process by generating purchase orders based on inventory levels, reducing the need for manual intervention and ensuring materials are ordered at the right time.

- Reducing waste and improving cost control: By tracking raw materials, work-in-progress items, and finished goods, MRP software helps businesses minimize waste, optimize production processes, and ultimately improve cost efficiency.

- Enhancing product quality and compliance: MRP software helps maintain quality control by tracking the components used in production and ensuring that materials meet the required standards and comply with industry regulations.

- Facilitating multi-location manufacturing operations: For businesses with multiple production facilities, MRP software allows for centralized control and coordination, helping streamline operations across various locations.

MRP Software Challenges and How to Overcome Them

While MRP software offers substantial benefits, implementing and using it can come with challenges. Understanding these potential roadblocks and knowing how to address them can help you ensure that the software delivers the desired results. Below are some common challenges businesses face and strategies to overcome them.

- Data Accuracy Issues: MRP systems rely heavily on accurate data to function effectively. Inaccurate inventory levels, wrong demand forecasts, or incorrect BOMs can result in production delays or inefficiencies.

Solution: Regularly audit and update your data to ensure accuracy. Use automated data entry tools to reduce the risk of human error and integrate the system with barcode scanners or RFID for real-time inventory updates. - Resistance to Change from Employees: Implementing new software can be met with resistance, especially if employees are used to legacy systems or manual processes.

Solution: Provide thorough training and clear communication about the benefits of the new system. Involve employees early in the process and address their concerns to ensure a smooth transition. - Complex Integration with Existing Systems: Integrating MRP software with other business systems like ERP or CRM can be challenging, especially if the systems are outdated or not compatible.

Solution: Work with the software provider to plan the integration process carefully. Choose an MRP system that offers pre-built integrations or flexible APIs to ensure smooth data exchange between systems. - Customization and Configuration Challenges: Many MRP systems require customization to fit the unique needs of a business, which can be time-consuming and costly.

Solution: Invest time in understanding your specific business needs before choosing an MRP system. Work closely with the vendor to ensure that the system is properly configured to suit your processes. - Overwhelming Complexity: Some MRP systems can be overly complex, especially for small businesses or companies with simpler manufacturing processes.

Solution: Look for an MRP system that matches your business size and complexity. Cloud-based or modular solutions are often a better fit for smaller businesses, offering essential features without unnecessary complexity. - Costs of Implementation and Maintenance: High upfront costs and ongoing maintenance expenses can be a concern, particularly for small or medium-sized businesses.

Solution: Choose an MRP system with a clear pricing structure that fits within your budget. Consider cloud-based solutions to avoid the need for costly hardware investments and IT maintenance.

By proactively addressing these challenges, you can better ensure that your MRP software implementation is successful and delivers the maximum benefits to your business.

Conclusion

Choosing the right MRP software can have a significant impact on your business’s ability to manage production, inventory, and procurement efficiently. With so many options available, it’s crucial to select a solution that fits the unique needs of your business, whether that’s scalability, customization, or industry-specific features. By carefully considering factors like company size, integration capabilities, and user-friendliness, you can ensure that the software you choose not only meets your current needs but also supports your growth in the future. The top MRP software solutions we’ve covered here provide a range of features to help businesses optimize their manufacturing processes and make smarter, data-driven decisions.

Remember, the right MRP software isn’t just about reducing costs or streamlining workflows—it’s about finding a tool that works for your team and helps you stay ahead of the competition. Take the time to evaluate your business’s specific challenges and growth potential before making a decision. Whether you go with a cloud-based solution for flexibility or a more traditional on-premise system for control, the right MRP system will support your business goals and help improve your overall manufacturing efficiency. Keep your priorities in mind, and you’ll be well on your way to selecting the best MRP software for your business.

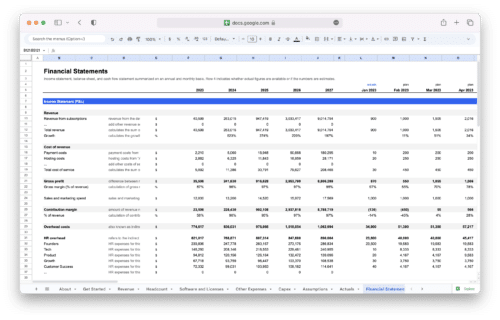

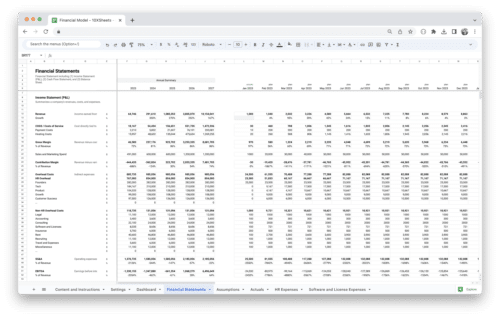

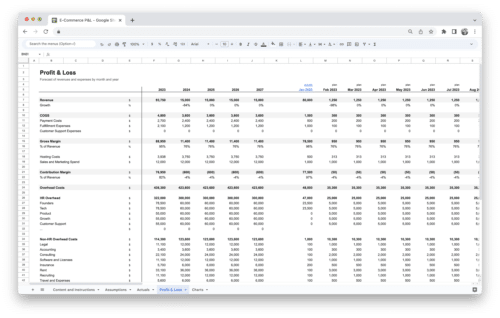

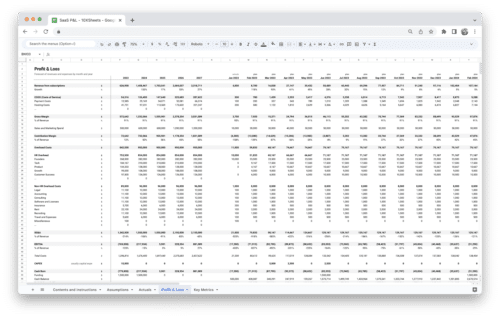

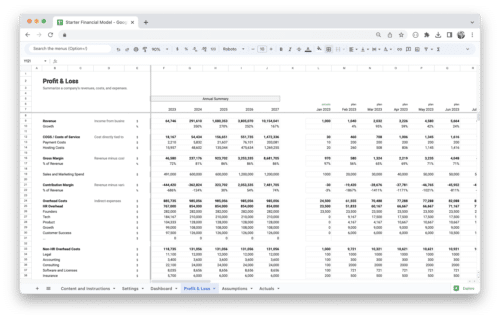

Get Started With a Prebuilt Template!

Looking to streamline your business financial modeling process with a prebuilt customizable template? Say goodbye to the hassle of building a financial model from scratch and get started right away with one of our premium templates.

- Save time with no need to create a financial model from scratch.

- Reduce errors with prebuilt formulas and calculations.

- Customize to your needs by adding/deleting sections and adjusting formulas.

- Automatically calculate key metrics for valuable insights.

- Make informed decisions about your strategy and goals with a clear picture of your business performance and financial health.

-

Sale!

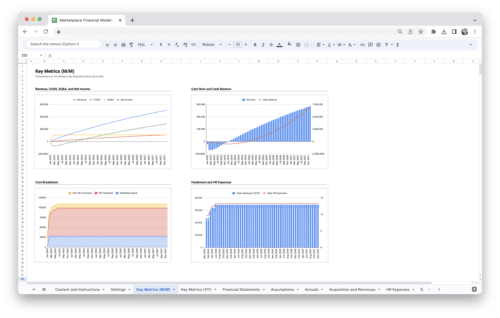

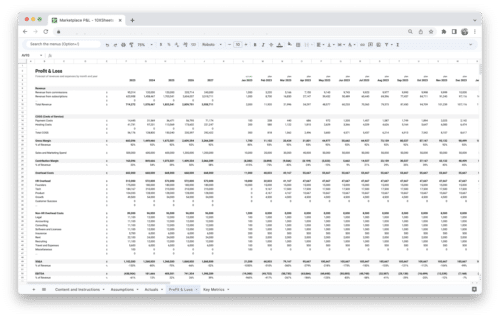

Marketplace Financial Model Template

Original price was: $219.00.$149.00Current price is: $149.00. Add to Cart -

Sale!

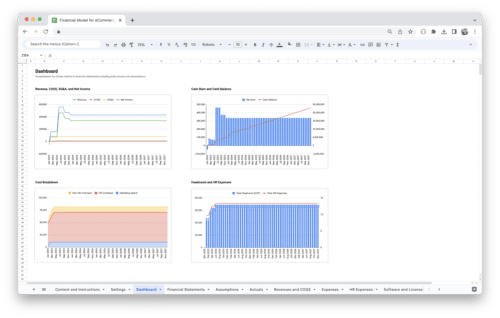

E-Commerce Financial Model Template

Original price was: $219.00.$149.00Current price is: $149.00. Add to Cart -

Sale!

SaaS Financial Model Template

Original price was: $219.00.$149.00Current price is: $149.00. Add to Cart -

Sale!

Standard Financial Model Template

Original price was: $219.00.$149.00Current price is: $149.00. Add to Cart -

Sale!

E-Commerce Profit and Loss Statement

Original price was: $119.00.$79.00Current price is: $79.00. Add to Cart -

Sale!

SaaS Profit and Loss Statement

Original price was: $119.00.$79.00Current price is: $79.00. Add to Cart -

Sale!

Marketplace Profit and Loss Statement

Original price was: $119.00.$79.00Current price is: $79.00. Add to Cart -

Sale!

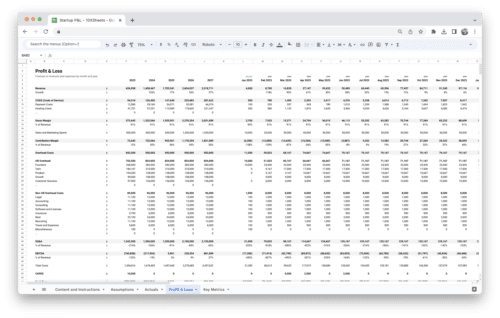

Startup Profit and Loss Statement

Original price was: $119.00.$79.00Current price is: $79.00. Add to Cart -

Sale!

Startup Financial Model Template

Original price was: $119.00.$79.00Current price is: $79.00. Add to Cart