Looking for the right software to improve your manufacturing operations? With so many options available, it can be overwhelming to choose the best one for your needs. Whether you’re looking to streamline production, improve inventory management, or ensure product quality, the right manufacturing software can help you run your business more efficiently.

This guide will help you navigate the various types of manufacturing software, the key features to look for, and the top solutions that can enhance your workflow and boost your bottom line.

What is Manufacturing Software?

Manufacturing software refers to a broad category of tools designed to help manufacturers plan, manage, and optimize various aspects of their operations. These tools streamline and automate processes that were once manual, such as inventory management, production scheduling, and quality control. By providing real-time insights and data-driven decision-making capabilities, manufacturing software helps businesses improve efficiency, reduce costs, and enhance product quality.

The core purpose of manufacturing software is to enable manufacturers to run their operations more smoothly and effectively. These systems integrate various functions into one cohesive platform, allowing teams from different departments—such as production, logistics, and sales—to work in alignment. Whether you’re managing a small assembly line or a large global supply chain, manufacturing software helps you improve the accuracy and speed of your processes.

Key purposes of manufacturing software include:

- Optimizing production schedules: Ensures the right materials and resources are available at the right time.

- Streamlining inventory management: Tracks raw materials, in-progress goods, and finished products across multiple locations.

- Enhancing quality control: Tracks product specifications, defects, and inspections to ensure consistent quality.

- Facilitating compliance: Assists in meeting industry regulations and standards through automated tracking and reporting.

Ultimately, manufacturing software serves as the backbone of a modern manufacturing operation, helping businesses deliver high-quality products efficiently while keeping costs in check.

Importance of Manufacturing Software in Modern Operations

As manufacturing environments become increasingly complex, the importance of manufacturing software cannot be overstated. In today’s fast-paced and globalized market, manufacturers are under constant pressure to increase production capacity, reduce lead times, and improve product quality. Without the right software tools, it would be nearly impossible to meet these demands efficiently.

- Efficiency: Manufacturing software eliminates manual processes, ensuring that production runs smoothly and resources are used effectively.

- Cost Reduction: Automation of various functions reduces labor costs and minimizes errors, leading to cost savings across operations.

- Real-Time Insights: Data collection and analysis capabilities allow manufacturers to make informed decisions quickly, ensuring faster response times to issues or opportunities.

- Global Operations: For manufacturers operating across multiple locations or markets, the ability to centralize data and synchronize operations is crucial for maintaining consistency and quality.

By integrating all key functions into one system, manufacturing software helps companies adapt to changing market conditions, improve competitiveness, and maintain profitability.

Benefits of Manufacturing Software

Manufacturing software offers a range of benefits that can significantly improve both operational and financial performance. These benefits extend beyond simple automation, enabling businesses to unlock new levels of efficiency, flexibility, and control.

- Improved efficiency: Automation of core processes such as scheduling, inventory management, and order processing reduces the need for manual work, cutting down on human error and delays.

- Enhanced decision-making: Real-time data and analytics provide managers with the insights they need to make informed decisions, from production adjustments to inventory reordering.

- Better quality control: Automated tracking of production parameters, defect reports, and inspections helps ensure that products meet strict quality standards, leading to fewer returns and higher customer satisfaction.

- Scalability: As your business grows, manufacturing software can scale with you. This includes supporting more complex workflows, larger data volumes, and the ability to integrate with additional systems.

- Cost savings: By optimizing production schedules, inventory management, and labor allocation, manufacturers can reduce waste, lower operating costs, and improve profitability.

- Compliance and regulatory support: Many manufacturing software systems help ensure compliance with industry regulations (e.g., ISO standards, FDA guidelines), reducing the risk of costly fines or recalls.

- Collaboration and communication: Centralized data allows teams across departments to collaborate more effectively, with transparent, up-to-date information available to all stakeholders.

With these benefits in mind, manufacturing software is no longer just a luxury—it’s a necessity for staying competitive in the modern manufacturing landscape.

Types of Manufacturing Software

Manufacturing software is a broad category that includes various tools designed to enhance different aspects of production processes. The right software for your business depends on your unique needs and operational focus. Below, we’ll explore the main types of manufacturing software, their roles, and how they can transform your business operations.

Enterprise Resource Planning (ERP) Systems

Enterprise Resource Planning (ERP) systems are designed to streamline and integrate the core processes of a business, including manufacturing. These systems help manage everything from inventory and procurement to financials, HR, and customer relationships. ERPs give you a holistic view of your company’s operations, which is vital for decision-making.

The main advantage of an ERP in manufacturing is that it centralizes data from all departments into one system, reducing silos and inefficiencies. For instance, production schedules are automatically updated based on sales orders, and inventory levels adjust in real-time as products are manufactured or shipped. This helps manufacturers to:

- Plan and manage resources efficiently.

- Track production status in real-time.

- Improve customer service by having up-to-date inventory and order status information.

- Achieve regulatory compliance with easier reporting.

Leading ERP systems like SAP, Oracle, and Microsoft Dynamics 365 provide modules specifically designed for manufacturing, making it easier for businesses to adapt their ERP systems to their production needs.

Manufacturing Execution Systems (MES)

Manufacturing Execution Systems (MES) bridge the gap between enterprise-level ERP software and the actual production floor. MES are designed to track and monitor the production process in real-time, providing actionable data on the shop floor.

These systems are incredibly valuable because they offer real-time insights into production activities, such as machine performance, work orders, and operator tasks. An MES allows you to:

- Monitor production in real-time and track progress against schedules.

- Detect bottlenecks and quality issues early, which can significantly reduce downtime.

- Automate tasks like order allocation and inventory updates.

- Ensure quality control by capturing detailed data on each step of production.

In short, MES ensures that the processes being planned at the enterprise level are being executed as efficiently as possible on the factory floor.

Product Lifecycle Management (PLM)

Product Lifecycle Management (PLM) software is focused on managing the entire lifecycle of a product, from its inception and design to its manufacturing, service, and eventual disposal. PLM is especially useful in industries where products are complex and have multiple components that must be tightly coordinated, such as aerospace, automotive, and electronics.

With PLM software, you can:

- Centralize product data and documentation in one place, ensuring that all teams work with the latest version.

- Manage product development from concept to production, allowing for easier design revisions.

- Track the product’s compliance with industry standards and regulations.

- Collaborate seamlessly with teams across different locations and departments, reducing errors and improving time-to-market.

A popular PLM system, like PTC Windchill or Siemens Teamcenter, can help companies optimize product design, engineering, and quality management, ultimately leading to better products and a smoother transition from design to manufacturing.

Supply Chain Management (SCM) Tools

Supply Chain Management (SCM) tools are designed to manage the flow of goods, information, and finances across your supply chain. These systems enable manufacturers to streamline procurement, production, and distribution, ensuring that materials are available when needed, and products are delivered on time.

SCM tools help manufacturers:

- Optimize inventory levels to reduce stockouts or excess inventory.

- Monitor supplier performance and collaborate closely with vendors to ensure timely deliveries.

- Analyze demand patterns to forecast needs more accurately.

- Improve logistics management to ensure products get to customers quickly and cost-effectively.

By using SCM tools like Oracle SCM Cloud or SAP Integrated Business Planning, you can ensure a more responsive and efficient supply chain, which directly translates to improved customer satisfaction and lower operational costs.

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) Systems

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems are essential for industries that design and produce custom products or parts. While CAD focuses on the design aspect, allowing engineers to create detailed 2D and 3D models of a product, CAM takes it a step further by automating the manufacturing process based on the CAD design.

These systems are crucial in:

- Improving design accuracy and reducing errors by providing precise blueprints for production.

- Enabling manufacturers to quickly modify and test designs virtually before moving to production.

- Streamlining production processes by directly linking designs to manufacturing equipment, such as CNC machines or 3D printers.

- Reducing lead times and increasing production flexibility.

Popular CAD and CAM systems, such as AutoCAD, SolidWorks, and Mastercam, offer powerful design tools and seamless integration with manufacturing processes. This reduces human error and enhances productivity, especially for companies focused on high-precision or custom-made products.

By leveraging CAD and CAM systems, manufacturers can accelerate the time from concept to production, improve product quality, and optimize their manufacturing workflows.

Top Manufacturing Software Solutions

When it comes to choosing the right manufacturing software, the number of available options can feel overwhelming. The key to finding the right solution lies in selecting a software that aligns with your specific needs, whether that’s for streamlining production, enhancing inventory management, or ensuring quality control. Below are some of the leading manufacturing software solutions that have earned a reputation for their comprehensive features and effectiveness.

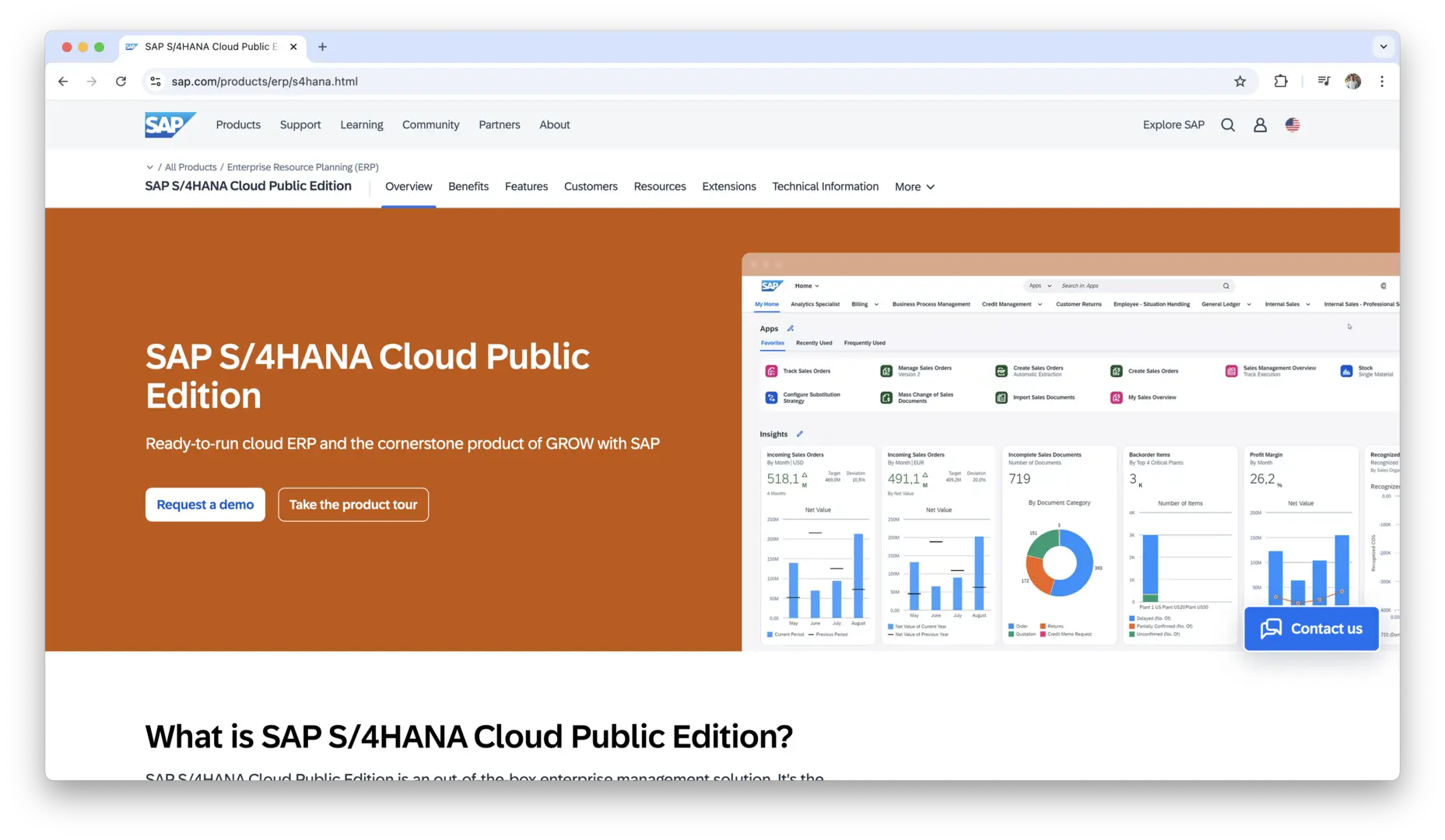

SAP S/4HANA

SAP S/4HANA is one of the most powerful ERP solutions available for manufacturing businesses. It offers a broad range of features, including real-time analytics, integrated supply chain management, and end-to-end visibility across the entire production process. Known for its scalability, SAP S/4HANA is ideal for large, complex manufacturing operations that require robust data management and the ability to manage global supply chains.

The system’s real-time data processing capability helps manufacturers make quick, informed decisions, particularly in industries like automotive, consumer goods, and chemicals. SAP S/4HANA integrates well with existing enterprise applications and is highly customizable, allowing manufacturers to tailor workflows to their specific needs.

Oracle NetSuite Manufacturing

Oracle NetSuite for Manufacturing is a cloud-based ERP platform that provides manufacturing businesses with comprehensive tools to manage everything from production planning and order management to financials and procurement. As a versatile solution, it’s especially useful for small to mid-sized manufacturers that need a flexible, cost-effective solution for managing multiple facets of their operations.

One of the standout features of Oracle NetSuite is its ability to integrate seamlessly with a variety of other business systems, including supply chain management, HR, and CRM. The software’s automated workflows and advanced reporting features allow businesses to track performance metrics and adjust production schedules accordingly. It also provides tools for inventory management, ensuring that stock levels are optimized and helping businesses avoid stockouts or overstocking.

Microsoft Dynamics 365

Microsoft Dynamics 365 is another popular ERP solution used by manufacturers worldwide. It brings together capabilities for finance, operations, and customer service into one integrated system, providing manufacturers with a comprehensive suite to streamline production and operations.

This platform’s AI-driven insights and predictive analytics help businesses anticipate production needs, manage inventory efficiently, and identify potential bottlenecks before they happen. Dynamics 365 is highly customizable, allowing manufacturers to fine-tune the software to meet the unique demands of their production environment. Its cloud-based infrastructure makes it a great option for businesses that need scalability and real-time access to data across multiple locations.

Epicor ERP

Epicor ERP & Business Management is known for its deep focus on the manufacturing industry, with tailored solutions for industries such as aerospace, automotive, and electronics. Epicor provides robust tools for production management, supply chain management, and HR, with an emphasis on improving operational efficiency and reducing costs.

Epicor’s intuitive user interface and strong integration capabilities make it easy to implement and use across different departments. The software’s forecasting and planning features help manufacturers predict demand, optimize production schedules, and enhance supply chain collaboration. For manufacturers looking to boost productivity and manage complex operations, Epicor ERP offers a reliable solution that can be scaled as the business grows.

Infor CloudSuite Industrial

Infor CloudSuite Industrial Manufacturing (formerly known as SyteLine) is a cloud-based manufacturing ERP solution that offers a range of tools for production management, supply chain planning, and financial tracking. It is specifically designed to meet the needs of discrete and process manufacturing industries, providing robust functionality for managing everything from inventory to advanced scheduling.

Infor’s advanced planning and scheduling (APS) tools help manufacturers optimize production timelines and improve resource allocation, while its integration with IoT devices allows for real-time data collection on the production floor. The software’s flexibility and scalability make it suitable for manufacturers of various sizes, particularly those in the industrial equipment and machinery sectors.

PTC Windchill

For manufacturers focused on product design and development, PTC Windchill is a top-tier Product Lifecycle Management (PLM) system that helps companies manage the entire lifecycle of their products—from conception to end-of-life. It integrates well with CAD and CAM systems and provides powerful tools for collaboration across design, engineering, and manufacturing teams.

Windchill enables teams to track product data, manage changes to designs, and collaborate on product development across departments. With advanced change management features and real-time access to product information, manufacturers can speed up the design-to-manufacturing process and ensure products meet quality standards. For companies that need deep control over product design and manufacturing processes, PTC Windchill is an ideal solution.

Shop-Ware

Shop-Ware is a specialized manufacturing software solution designed for small to mid-sized businesses, particularly in the wholesale and distribution sectors. It integrates manufacturing processes with an intuitive e-commerce platform, enabling manufacturers to track orders, manage inventory, and streamline their production processes from one central hub.

The software allows manufacturers to create customizable workflows based on their specific production needs. It also provides real-time insights into inventory levels, making it easier to plan production schedules and ensure timely delivery of products. Shop-Ware’s focus on simplicity and ease of use makes it an attractive option for businesses that require a user-friendly, cost-effective solution for managing their operations.

Siemens Teamcenter

Siemens Teamcenter is a leading PLM software solution that supports manufacturers in managing their product development processes. It integrates data across the entire product lifecycle, from design and engineering to manufacturing and service. Teamcenter provides a centralized repository for product data, helping teams collaborate on designs and track changes more efficiently.

With features such as advanced simulation tools, materials management, and compliance tracking, Teamcenter is particularly beneficial for manufacturers in industries like aerospace, automotive, and industrial equipment. By enabling better collaboration and data management, Siemens Teamcenter helps businesses improve product quality, speed up time-to-market, and ensure regulatory compliance.

Autodesk Fusion 360

Autodesk Fusion 360 is a powerful cloud-based 3D CAD, CAM, and CAE software that brings design and manufacturing teams together on a single platform. It is ideal for product designers, engineers, and manufacturers who need a unified solution for product development and prototyping. Fusion 360 allows for real-time collaboration, version control, and design-to-manufacturing workflows, helping teams work more efficiently. The software integrates CAD and CAM tools, enabling designers to create detailed models and generate machine-ready instructions, all in one platform. With cloud-based storage, teams can collaborate from anywhere, making it especially valuable for remote or distributed teams.

Fishbowl Manufacturing

Fishbowl Manufacturing is an all-in-one inventory management and manufacturing solution designed for small and mid-sized businesses. It provides tools to manage production processes, including work orders, raw material inventory, and finished goods. Fishbowl automates the entire inventory cycle, allowing businesses to track stock levels, avoid stockouts, and reduce overstocking. Additionally, it offers advanced reporting capabilities, helping manufacturers track production efficiency and make data-driven decisions. Fishbowl also integrates with popular accounting systems like QuickBooks, making it easier to manage finances alongside inventory and production.

JustFood Bakery Software

Tailored specifically to the food industry, JustFood Bakery Software is designed to help bakeries and food manufacturers manage production, quality control, and traceability. It ensures compliance with food safety regulations while optimizing operations. Features include ingredient tracking, recipe management, and batch production scheduling, ensuring that bakeries can scale efficiently. The software also provides tools for managing allergens, label printing, and quality assurance testing, making it easier to stay compliant with industry standards. JustFood Bakery Software helps businesses improve product consistency, manage inventory effectively, and minimize waste.

Plex Manufacturing Cloud

Plex Manufacturing Cloud is a comprehensive, cloud-based ERP solution designed specifically for manufacturers. It covers a wide range of processes, including production management, supply chain tracking, inventory control, and financial management. Plex offers real-time visibility into manufacturing operations, making it easier to monitor progress, detect issues, and optimize workflows. The cloud-based nature of the software ensures that businesses can access critical data from anywhere, at any time. With advanced analytics and reporting tools, Plex allows manufacturers to make smarter decisions based on real-time performance metrics, improving productivity and reducing operational costs.

SYSPRO ERP

SYSPRO is an ERP system that provides specialized solutions for the manufacturing sector, particularly suited for industries like food and beverage, electronics, and metals. The platform offers comprehensive tools for production scheduling, inventory management, and procurement, helping manufacturers optimize their operations and reduce costs. SYSPRO’s user-friendly interface and customizable features make it a great choice for businesses of all sizes. The system also integrates with other business functions such as finance, sales, and HR, providing a complete picture of the entire business ecosystem. SYSPRO’s flexibility and scalability ensure that it can grow with your business.

QAD Cloud ERP

QAD Cloud ERP is a modern, cloud-based solution built for manufacturers in industries such as automotive, life sciences, and consumer products. It provides end-to-end functionality for managing production processes, supply chain management, inventory, procurement, and finance. QAD’s cloud-based platform offers real-time data access, making it easy for manufacturers to track and manage their operations from any location. The software also includes advanced analytics and reporting tools, which help businesses optimize production schedules, reduce downtime, and improve overall efficiency. QAD’s focus on the manufacturing sector allows it to offer tailored features that meet the specific needs of industrial businesses.

Infor M3

Infor M3 is a powerful ERP system designed for complex manufacturing environments. It’s particularly beneficial for industries like food and beverage, chemicals, and fashion. M3 provides comprehensive tools for managing production planning, inventory, procurement, and supply chain operations. The platform’s advanced features for planning and scheduling help manufacturers optimize workflows, reduce bottlenecks, and increase overall efficiency. Infor M3 also offers strong reporting and analytics capabilities, allowing businesses to make data-driven decisions. The system’s cloud-based architecture makes it easily scalable, supporting global operations and multi-site management.

ProShop ERP

ProShop ERP is a specialized ERP solution for manufacturers in the precision machining and job shop industries. It offers powerful features for job tracking, production planning, inventory management, and quality control. ProShop’s unique focus on the machining industry means that it provides deep functionality for tracking part specifications, work orders, and machine utilization. The software integrates with shop floor data collection systems, providing real-time updates on production status and machine performance. ProShop’s highly customizable solution allows businesses to tailor the system to their unique workflows, enhancing productivity and reducing errors.

RazorERP

RazorERP is a cloud-based ERP system designed for small and mid-sized manufacturers. It covers key areas of business management, including inventory, procurement, production, and accounting. RazorERP’s user-friendly interface and affordable pricing make it an ideal choice for businesses that need a cost-effective solution without sacrificing functionality. The software includes features for managing orders, tracking inventory, and optimizing production schedules, helping businesses improve efficiency and reduce costs. RazorERP also offers cloud-based deployment, which means that manufacturers can access their data from anywhere, ensuring flexibility and scalability as their business grows.

SAP Business One

SAP Business One is an ERP solution designed for small to medium-sized businesses, offering a comprehensive suite of tools for managing manufacturing processes. SAP Business One includes modules for production planning, inventory management, procurement, and financials. The system helps businesses streamline operations by automating key processes, reducing manual effort, and improving accuracy. SAP Business One also integrates with other SAP solutions, providing a scalable platform that can grow with the business. Its intuitive interface and customizable features make it suitable for a wide range of industries, from manufacturing to retail.

Each of these solutions offers unique features that cater to specific needs within manufacturing environments. Whether you are looking for robust ERP solutions, advanced PLM systems, or cloud-based tools, the right software can significantly enhance your manufacturing operations, boosting productivity, improving quality control, and driving business growth.

Features to Look for in Manufacturing Software

When choosing manufacturing software, it’s essential to focus on the key features that will optimize your production processes, improve efficiency, and reduce costs. Here are the critical features to look for when selecting the right software solution for your business.

Inventory and Supply Chain Management

Effective inventory and supply chain management are at the heart of any successful manufacturing operation. Manufacturing software should provide real-time visibility into your inventory levels, helping you track raw materials, work-in-progress items, and finished goods.

By having access to live data about inventory, you can:

- Reduce stockouts: Real-time data ensures you’re aware when inventory levels are running low, so you can reorder materials before running out.

- Avoid excess stock: It also helps to prevent over-ordering or stockpiling, which can result in wasted space and capital.

- Streamline procurement: You can automate the purchasing process by setting up triggers for automatic reordering based on predefined thresholds.

- Optimize supplier relationships: With supply chain management capabilities, you can track supplier performance, negotiate better terms, and ensure that shipments arrive on time.

Many advanced software solutions also offer features like demand forecasting, which can help you predict future material needs based on historical sales data, production schedules, and market trends.

Production Scheduling and Tracking

Production scheduling is a key component that enables you to plan and execute your manufacturing processes effectively. A good manufacturing software solution will provide tools for creating efficient production schedules that align with available resources, workforce capacity, and customer demand.

The ability to:

- Plan ahead: Production scheduling tools help you allocate resources and schedule tasks based on real-time conditions. This ensures you have the right resources available when needed, reducing idle time.

- Track progress: Once production is underway, the software should allow you to track the progress of each work order or production batch in real-time. You can monitor whether the team is on schedule and whether there are any delays or disruptions.

- Prioritize tasks: When unexpected challenges arise, you can adjust your production schedule in real-time to prioritize urgent orders or balance workloads across production lines.

- Manage capacity: Scheduling tools also help ensure that machines and employees are utilized efficiently, avoiding overburdening any single production area.

By using production scheduling and tracking, you can improve throughput, reduce downtime, and ultimately increase the reliability of your delivery schedules.

Real-Time Data Collection and Reporting

Real-time data collection is one of the most valuable features of modern manufacturing software. In a fast-paced production environment, having immediate access to live data is crucial for making informed decisions and taking timely action.

Manufacturing software should collect data from various production sources, including machines, operators, sensors, and quality checks, and present it in a user-friendly dashboard. This feature enables you to:

- Monitor performance: Track key performance indicators (KPIs) such as machine uptime, operator productivity, and inventory turnover, allowing you to make adjustments as needed.

- Identify bottlenecks: Real-time data helps identify inefficiencies and bottlenecks early in the production process, enabling you to act before small issues become big problems.

- Make quick decisions: With instant access to critical data, you can make real-time decisions, such as adjusting machine settings, reallocating resources, or adjusting production schedules to accommodate new orders.

- Generate reports: The software should allow you to create customizable reports on various aspects of your operations, providing insights that can help improve processes or guide strategic decisions.

The ability to gather, analyze, and act on real-time data can significantly enhance operational efficiency, reduce waste, and support data-driven decision-making.

Quality Control and Compliance

Quality control is one of the most critical aspects of any manufacturing operation, especially in industries with strict regulatory requirements. Manufacturing software should include robust tools for managing quality control and ensuring that your products meet the highest standards.

Key quality control features to look for include:

- Inspection management: The software should allow you to track the results of inspections and tests throughout the production process. This could include checking for defects, ensuring product specifications are met, and recording measurements.

- Defect tracking: If defects are detected, you should be able to track them, analyze root causes, and implement corrective actions to prevent future issues. Quality management systems (QMS) integrated with manufacturing software help maintain detailed records of non-conformances, ensuring traceability.

- Automated alerts: Automated alerts can be set up to notify managers when quality deviations occur, allowing you to address problems as they arise.

- Regulatory compliance: Manufacturing software that focuses on compliance will help ensure that your operations meet industry-specific regulations and standards, such as ISO certifications, FDA regulations, or environmental standards. It should also help you maintain accurate documentation for audits.

A strong quality control and compliance framework within your manufacturing software can help you reduce defects, improve customer satisfaction, and minimize the risk of costly fines or recalls.

Integration with Other Business Systems

For manufacturing software to be truly effective, it must be able to seamlessly integrate with other business systems, such as ERP, CRM, HR, and finance tools. Integration ensures that data flows smoothly between departments, eliminating silos and reducing the risk of errors.

Key integrations to look for include:

- ERP Integration: The ability to sync manufacturing data with your ERP system ensures that sales, finance, and procurement teams are working with accurate, up-to-date information.

- CRM Integration: If your software integrates with Customer Relationship Management (CRM) systems, you can better align your production schedules with customer orders and demands.

- HR and Payroll Integration: Integration with HR systems allows you to manage labor costs, track employee performance, and even schedule workforce availability based on production needs.

- Accounting and Finance Integration: Linking manufacturing software with accounting systems enables you to track production costs, manage budgets, and streamline invoicing processes.

The seamless flow of data between systems helps prevent data duplication, reduces the need for manual entry, and ensures everyone is on the same page. When your manufacturing software integrates effectively with other tools, you can enhance overall productivity and make more informed business decisions.

Manufacturing Software Integration and Customization

When selecting manufacturing software, one of the most critical factors is its ability to integrate seamlessly with your existing systems and workflows. The right software should offer flexibility and adaptability, allowing you to customize it according to your specific business needs.

Customization and integration are key to ensuring that your software enhances, rather than disrupts, your operations. Here are some important considerations to keep in mind:

- System Compatibility: Ensure that the software integrates easily with your current Enterprise Resource Planning (ERP), Supply Chain Management (SCM), and Customer Relationship Management (CRM) systems, as well as other tools you already use.

- Data Synchronization: A good manufacturing software solution should provide real-time data synchronization across systems, reducing manual entry and the risk of errors.

- Custom Workflows: You should be able to tailor the software to meet the specific workflows of your manufacturing process, whether that’s production scheduling, inventory management, or quality control.

- User Interface (UI) Personalization: Customizing the user interface can help make the system more intuitive and easy to use for different departments within your company.

- Scalability: As your company grows, your software should be able to scale to accommodate increased production, more complex workflows, and additional integration points with other business systems.

- Third-Party Integrations: Look for software that can easily integrate with third-party applications, such as data analytics tools, IoT sensors, and external supplier networks, to optimize your operations further.

- Cloud vs. On-Premise Customization: Depending on whether you choose a cloud-based or on-premise solution, customization options and flexibility may vary. Cloud-based solutions often offer more rapid updates and easier integration, while on-premise systems may provide deeper control over security and infrastructure.

By ensuring your manufacturing software can be fully integrated and customized, you’ll improve the flow of information across departments, reduce inefficiencies, and better align your software with your business objectives.

Manufacturing Software Implementation Challenges and Solutions

Implementing new manufacturing software is a complex process, and like any major change, it comes with its own set of challenges. Understanding these challenges in advance will help you navigate the transition smoothly and ensure that you maximize the value of the software from day one.

While there are many challenges, most can be mitigated with proper planning, communication, and support. Here’s a look at some of the most common obstacles and potential solutions:

- Resistance to Change: Employees may be hesitant to adopt new software, especially if they are accustomed to older systems. Solution: Involve key stakeholders early in the decision-making process, provide proper training, and emphasize the benefits of the new system to gain buy-in.

- Data Migration: Transferring data from legacy systems to a new platform can be time-consuming and prone to errors. Solution: Plan for a structured data migration process, test the migration thoroughly before going live, and consider using data migration tools provided by the software vendor.

- Customization Complexity: While customization is important, excessive customization can complicate the implementation and increase costs. Solution: Focus on customizing the most critical aspects of the system that will drive value, and avoid unnecessary alterations that may complicate future updates.

- Integration Issues: Ensuring the new software integrates seamlessly with existing systems can be challenging. Solution: Work closely with the software provider to understand integration requirements and leverage their support team for a smooth integration process.

- Inadequate Training: If employees don’t fully understand how to use the new system, they may not take full advantage of its capabilities. Solution: Provide thorough training sessions for all users and offer continuous support as employees become more familiar with the system.

- Cost Overruns: The total cost of implementation, including software, customization, and training, can sometimes exceed expectations. Solution: Develop a clear implementation budget upfront and work closely with the software vendor to understand all potential costs. Include contingency funds for unforeseen expenses.

- Downtime During Transition: Switching to a new system can cause temporary disruptions in production. Solution: Plan the implementation during off-peak periods or schedule the switch during low-demand times to minimize the impact on production.

- Ongoing Support and Maintenance: After implementation, ongoing support and maintenance are essential to keeping the system running smoothly. Solution: Ensure that you have access to a dedicated support team from the software vendor, and establish an internal support structure to handle common issues.

By addressing these common implementation challenges head-on, you can ensure a smooth transition to your new manufacturing software, with minimal disruption to your operations.

Conclusion

Choosing the right manufacturing software is crucial to the efficiency and success of your operations. Whether you need an ERP system to manage resources, a PLM tool for product development, or software for better inventory control, the right choice can streamline your processes, save time, and reduce costs. The top solutions we’ve discussed provide a variety of features designed to meet different business needs, from small manufacturers to large, global operations. By understanding your unique requirements and comparing available options, you can find the software that best fits your company’s goals.

As you evaluate your options, consider factors like integration with existing systems, customization capabilities, and scalability to ensure the software can grow with your business. Take the time to assess both the immediate needs and future growth of your operations. With the right manufacturing software in place, you’ll be well-positioned to enhance productivity, improve product quality, and make more informed decisions that drive long-term success.

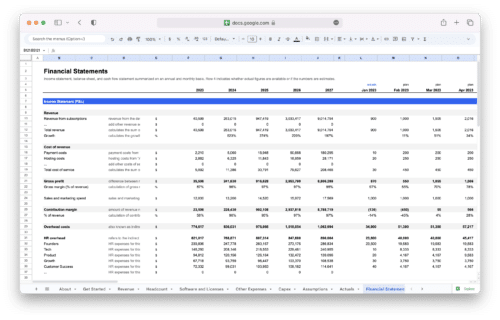

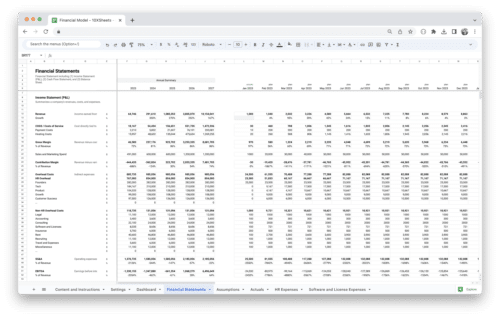

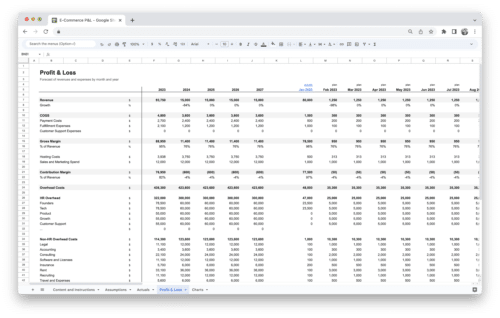

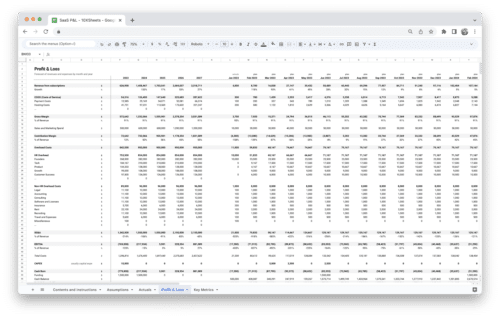

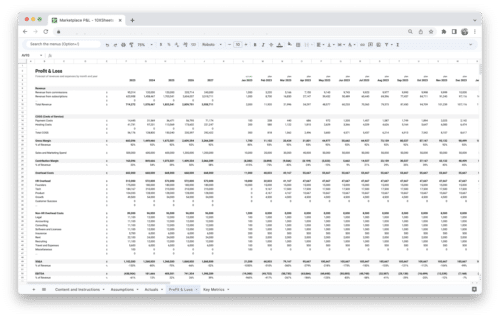

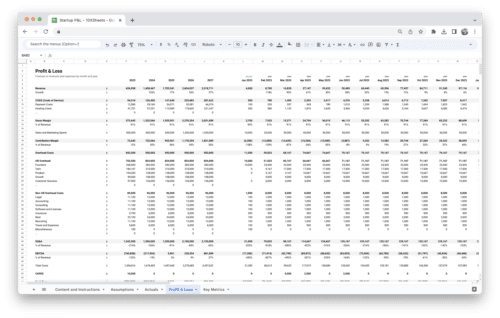

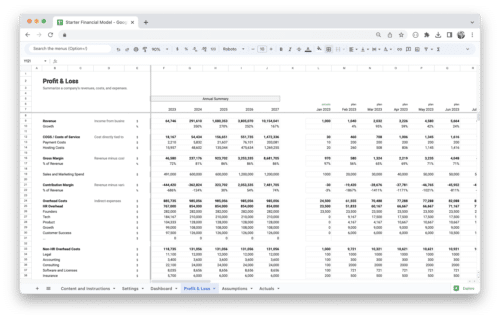

Get Started With a Prebuilt Template!

Looking to streamline your business financial modeling process with a prebuilt customizable template? Say goodbye to the hassle of building a financial model from scratch and get started right away with one of our premium templates.

- Save time with no need to create a financial model from scratch.

- Reduce errors with prebuilt formulas and calculations.

- Customize to your needs by adding/deleting sections and adjusting formulas.

- Automatically calculate key metrics for valuable insights.

- Make informed decisions about your strategy and goals with a clear picture of your business performance and financial health.

-

Sale!

Marketplace Financial Model Template

Original price was: $219.00.$149.00Current price is: $149.00. Add to Cart -

Sale!

E-Commerce Financial Model Template

Original price was: $219.00.$149.00Current price is: $149.00. Add to Cart -

Sale!

SaaS Financial Model Template

Original price was: $219.00.$149.00Current price is: $149.00. Add to Cart -

Sale!

Standard Financial Model Template

Original price was: $219.00.$149.00Current price is: $149.00. Add to Cart -

Sale!

E-Commerce Profit and Loss Statement

Original price was: $119.00.$79.00Current price is: $79.00. Add to Cart -

Sale!

SaaS Profit and Loss Statement

Original price was: $119.00.$79.00Current price is: $79.00. Add to Cart -

Sale!

Marketplace Profit and Loss Statement

Original price was: $119.00.$79.00Current price is: $79.00. Add to Cart -

Sale!

Startup Profit and Loss Statement

Original price was: $119.00.$79.00Current price is: $79.00. Add to Cart -

Sale!

Startup Financial Model Template

Original price was: $119.00.$79.00Current price is: $79.00. Add to Cart